Improving the Efficiency of Hot Rolling Mill.

Introduction – Hot rolling mills play a crucial role in the manufacturing process of various metal products. These mills transform metal ingots into desired shapes and sizes through a series of heating, rolling, and cooling processes. However, ensuring maximum efficiency in hot rolling mills is a constant challenge for manufacturers. In this article, we will explore several strategies and techniques to enhance the efficiency of hot rolling mills, ultimately leading to improved productivity and cost-effectiveness. Meta TechX Blog

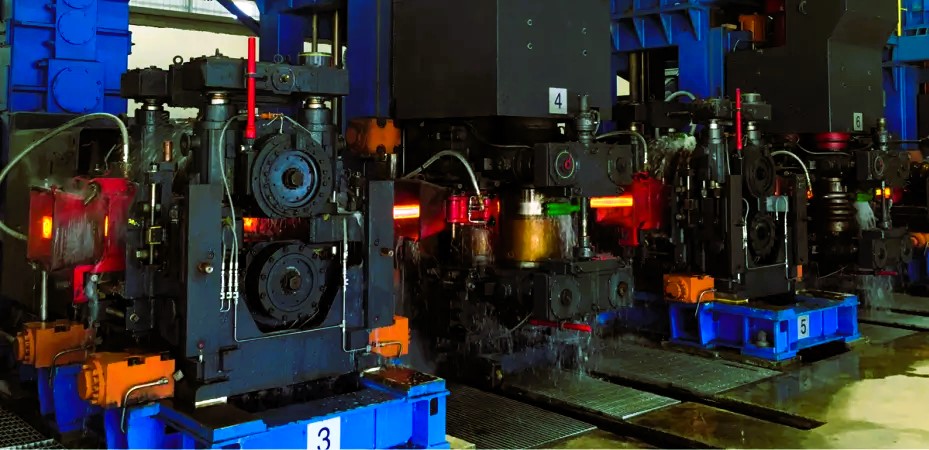

Understanding Hot Rolling Mills

Before delving into the methods of improving efficiency, it is essential to have a basic understanding of hot rolling mills. These mills consist of various components, including a reheating furnace, a rolling mill stand, and a cooling bed. The process starts with the reheating furnace, where metal ingots/billets are heated to their plastic state. Once heated, the ingots pass through the rolling mill stand, where they are flattened and shaped into desired profiles. Finally, the cooled products are transported to the cooling bed for further processing.

Proper Maintenance and Lubrication

One of the key factors in improving the efficiency of hot rolling mills is regular maintenance and lubrication. Ensuring that all components are properly maintained and lubricated minimizes the risk of breakdowns and extends the lifespan of the equipment. Regular inspections should be conducted to identify any signs of wear and tear, such as worn bearings or damaged rollers. Additionally, using high-quality lubricants reduces friction and improves the overall performance of the mill.

Optimal Operating Parameters

To achieve maximum efficiency, it is crucial to operate the hot rolling mill within the optimal parameters. This involves maintaining the correct rolling temperature, roll force, and rolling speed. Deviation from these parameters can result in poor product quality and increased energy consumption. By closely monitoring and adjusting the operating parameters, manufacturers can achieve higher productivity and minimize material waste.

Automation and Digitization

In today’s digital era, automation and digitization have become indispensable tools for improving efficiency in various industries, including hot rolling mills. Automated systems can monitor and control the mill’s operating parameters in real-time, ensuring precise and consistent results. Additionally, digitization allows for the collection and analysis of vast amounts of data, enabling manufacturers to identify areas of improvement and optimize the mill’s performance.

Employee Training and Skill Development

Although technology plays a vital role in enhancing efficiency, the competence of mill operators should not be overlooked. Providing comprehensive training programs and opportunities for skill development can significantly contribute to maximizing the efficiency of hot rolling mills. Well-trained operators can identify potential issues, make informed decisions, and operate the mill more effectively, leading to improved productivity and reduced downtime. Join Meta TechX Engineers…

Implementing Energy-Saving Measures

In the pursuit of improved efficiency, it is essential to consider energy-saving measures within hot rolling mills. Energy-intensive processes, such as heating and cooling, can significantly impact operational costs. By adopting energy-efficient technologies and practices, such as utilizing waste heat recovery systems or implementing energy management systems, manufacturers can reduce energy consumption and lower their environmental footprint.

Conclusion

Efficiency is paramount in the operation of hot rolling mills, as it directly impacts productivity, cost-effectiveness, and product quality. By focusing on proper maintenance, optimal operating parameters, automation, employee training, and energy-saving measures, manufacturers can strive towards improving the efficiency of their hot rolling mills. Embracing these strategies will not only enhance performance but also contribute to the overall growth and success of the metal manufacturing industry.

Learn effective strategies to improve the efficiency of hot rolling mills, including proper maintenance, optimal operating parameters, automation, employee training, and energy-saving measures. Start maximizing productivity and cost-effectiveness today! Meta TechX Engineers…