Enhancing the lifespan of work rolls in a hot rolling mill is crucial for improving productivity, reducing maintenance costs, and ensuring consistent product quality. Several key criteria should be considered to achieve this goal:

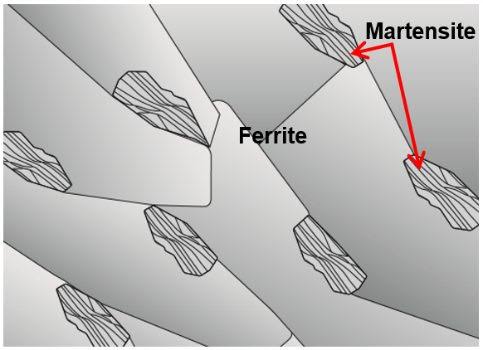

- Material Selection: Work rolls are typically made from high-speed tool steels, such as High-Speed Steel (HSS) or tool steels containing tungsten, molybdenum, and vanadium. These materials offer excellent wear resistance, toughness, and thermal stability, which are essential for withstanding the harsh conditions of hot rolling.

- Surface Coatings and Treatments: Applying surface coatings or treatments can significantly improve the wear resistance and thermal properties of work rolls. Examples include:

- Chrome plating: Provides excellent wear resistance and corrosion protection.

- Thermal spray coatings: Deposits materials like tungsten carbide or ceramics onto the roll surface, enhancing wear resistance.

- Nitriding: Introduces nitrogen into the surface layer of the roll, improving hardness and wear resistance.

- Shot peening: Induces compressive stresses on the surface, improving fatigue resistance and preventing crack propagation.

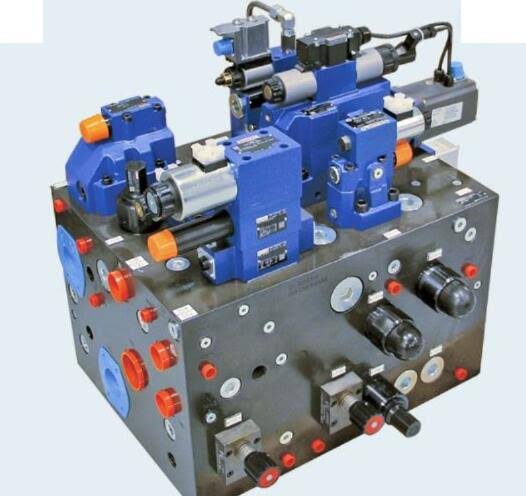

- Proper Cooling and Lubrication: Effective cooling and lubrication systems are essential for controlling the temperature and reducing friction between the workpiece and rolls. Proper cooling helps prevent thermal fatigue and extends the lifespan of the rolls. Lubricants reduce friction and wear, minimizing surface damage and improving surface finish.

- Optimized Rolling Parameters: Adjusting rolling parameters such as rolling speed, reduction ratio, and roll gap can help reduce the mechanical and thermal stresses experienced by the work rolls. Operating within recommended limits and avoiding excessive loads can extend roll life and prevent premature failure.

- Regular Maintenance and Inspection: Implementing a proactive maintenance schedule is crucial for detecting early signs of wear or damage on the work rolls. Regular inspections, including visual inspections, dimensional measurements, and non-destructive testing, can help identify potential issues before they escalate.

- Roll Grinding and Profile Maintenance: Proper grinding of work rolls helps maintain their surface finish and dimensional accuracy. Regular grinding removes surface imperfections and restores the desired profile, ensuring consistent product quality and prolonging roll life.

- Roll Handling and Storage: Proper handling and storage practices are essential for preventing damage to the work rolls during transportation, installation, and storage. Rolls should be handled with care to avoid dents, scratches, or other surface defects that can affect performance.

By addressing these major criteria and implementing best practices, hot rolling mills can enhance the lifespan of work rolls, leading to improved efficiency, reduced downtime, and overall cost savings. Regular monitoring and continuous improvement efforts are key to maximizing roll performance and optimizing mill operations.