Meta TechX Engineers – An Electric induction furnace is a type of furnace used for melting metal and creating various metal products. It is widely utilized in the manufacturing industry due to its efficiency, precision, and versatility. Induction furnaces use electromagnetic induction to generate heat, resulting in a controlled and energy-efficient melting process. The principle behind how an induction furnace works is fascinating and complex, so let’s delve into the details to better understand this innovative technology.

How Does an Induction Furnace Work?Electromagnetic Induction:At the core of an induction furnace lies the principle of electromagnetic induction. This principle was first discovered by Michael Faraday in the early 19th century and forms the foundation of how an induction furnace operates. Electromagnetic induction involves the generation of an electric current in a conductor when it experiences a changing magnetic field.

1- Induction Coil: The primary component of an induction furnace is the induction coil, also known as the inductor. This coil consists of a copper pipe or tubing wound into a helical shape. When an alternating electric current passes through the coil, it generates a continually changing magnetic field around it.

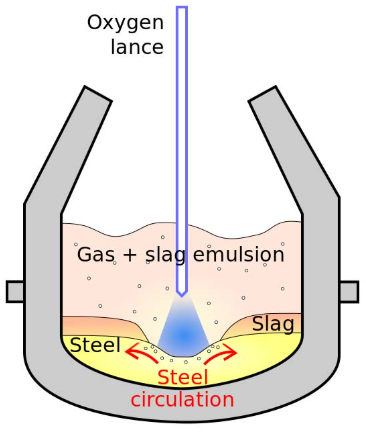

2- Eddy Currents: When a conductive material, such as metal, is placed within the changing magnetic field of the induction coil, eddy currents are induced within the material. These currents circulate within the metal, creating localized heat due to electrical resistance. The intensity of the heat is directly proportional to the strength of the induced current.

3- Melting Process: To facilitate the melting process, the metal to be melted is placed within a crucible made of a refractory material capable of withstanding high temperatures. The crucible is positioned within the induction coil, allowing the generated magnetic field to interact with the metal.As the eddy currents flow through the metal, the resistance encountered converts electrical energy into heat. This heat gradually raises the temperature of the metal, eventually melting it. The precise control of the electromagnetic field in an induction furnace enables operators to achieve and maintain specific melting temperatures with accuracy.

4- Pouring and Casting: Once the metal has reached its desired melting point, it is ready for further processing. The molten metal can be poured directly into molds to create various shapes or transferred to other equipment for refining and forming processes. The versatility of induction furnaces allows for easy adaptation to different casting techniques, making them invaluable in a wide range of industries.

Advantages of Induction Furnaces: Induction furnaces offer numerous advantages over other forms of melting technology, leading to their widespread adoption in the manufacturing sector.

1. High Efficiency: Induction furnaces are known for their exceptional energy efficiency. Since the heat is generated directly in the metal, there is minimal energy wastage, making it more economical compared to other types of furnaces.

2. Precise Control: Induction furnaces offer precise temperature control, allowing operators to melt metals at specific temperatures and maintain them throughout the melting process. This precision proves beneficial in achieving desired metallurgical properties.

3. Fast Melting: Induction furnaces facilitate rapid melting of metals due to the intense heat generated by electromagnetic induction. This efficiency not only saves time but also increases production output.

4. Cleaner Operations: Unlike furnaces that rely on fossil fuels, induction furnaces operate using electricity. This electric operation eliminates the emission of greenhouse gases and minimizes pollution, making them environmentally friendly.

5. Versatility: Induction furnaces can melt a wide range of metals, including steel, iron, copper, aluminum, and alloys. Their ability to handle different types of metals makes them a popular choice in various industries.

Disadvantages of Induction Furnaces

1. Higher Initial Cost: Induction furnaces often have a higher upfront cost compared to other types of furnaces. This initial investment can deter some businesses, especially smaller ones, from adopting this technology.

2. Complex Installation and Maintenance: The installation and maintenance of induction furnaces require technical expertise and specialized equipment. This complexity can increase the overall operating costs and may require skilled personnel for upkeep.

3. Power Supply Requirements: Induction furnaces require a substantial amount of electricity to operate efficiently. Establishing a reliable power supply system is crucial to ensure uninterrupted operation.

Conclusion:

An induction furnace is a powerful tool in the metalworking industry, employing electromagnetic induction to melt a wide range of metals. Its energy efficiency, precise temperature control, fast melting capabilities, and versatility make it a desirable choice for various applications. While it may have some drawbacks, the advantages outweigh the disadvantages, making induction furnaces an excellent investment for businesses aiming for high-quality metal melting and processing operations.