Meta TechX Engineers: When it comes to hydraulic systems, manifold valves play a crucial role in ensuring efficient and precise control over fluid flow. But what exactly is a manifold valve in hydraulic systems, how does it operate, and what are its components and advantages? In this article, we will dive deep into the world of manifold valves, exploring their functionality and the benefits they bring to hydraulic systems.

What is a Manifold Valve in Hydraulic Systems?

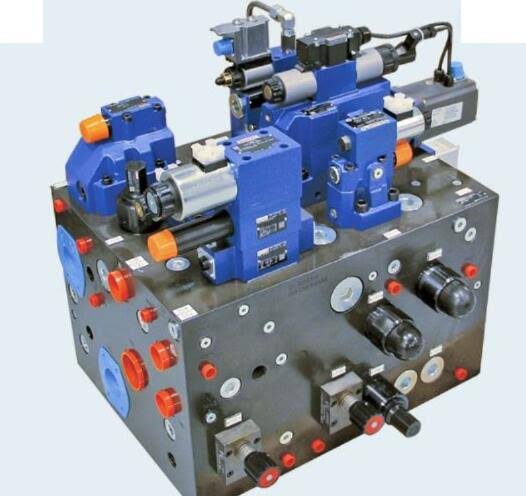

A manifold valve, also known as a hydraulic valve manifold, is a crucial component in hydraulic systems that helps control the flow of fluids. This valve is designed to connect multiple hydraulic components, such as cylinders and motors, to a single power source. By regulating the fluid flow, manifold valves enable operators to control the direction, pressure, and volume of hydraulic actuators.

How Does a Manifold Valve Operate?

Manifold valves operate through a combination of mechanical and hydraulic principles. When fluid flow needs to be controlled, the manifold valve receives signals from the system’s control devices, such as push buttons or levers. These signals are then transmitted to the valve’s internal spool, which regulates the flow of fluid by opening or closing specific ports within the valve body.

The spool inside the manifold valve moves back and forth, aligning itself with different ports to allow or block fluid flow. By adjusting the position of the spool, operators can control the direction of fluid, adjust pressure levels, and achieve precise control over hydraulic system operations.

Components of a Manifold Valve

A manifold valve is composed of several key components that work together to ensure smooth and accurate fluid control. Let’s take a closer look at these components:

- Valve Body: This is the main housing of the manifold valve, which contains all the critical components and fluid passages. It is typically made of durable materials such as stainless steel or aluminum to withstand high-pressure applications.

- Spool: The spool is a crucial element responsible for regulating fluid flow. It moves within the valve body to align with different ports, allowing or blocking the movement of fluid.

- Actuators: Manifold valves may incorporate various types of actuators, including solenoids, manual levers, or hydraulic pistons. These actuators control the movement of the spool, enabling operators to manipulate fluid flow easily.

- Ports: Manifold valves have multiple ports that provide entry and exit points for fluid. These ports connect the valve to other hydraulic components, such as cylinders and motors.

- Seals: Seals are essential for preventing leaks and ensuring the integrity of the fluid system. They help maintain the necessary pressure levels within the valve body, minimizing the risk of fluid loss.

Advantages of Using Manifold Valves

Using manifold valves in hydraulic systems offers numerous advantages, making them a preferred choice in many industrial applications. Here are some key benefits:

- Compact Design: Manifold valves are designed to integrate multiple functions into a single unit, reducing the need for separate valves. This compact design not only saves space but also simplifies installation and maintenance processes.

- Precise Control: With the ability to adjust fluid flow, manifold valves enable operators to achieve precise control over hydraulic system operations. This level of control ensures the smooth and accurate movement of actuators, enhancing overall system performance.

- Improved Efficiency: By eliminating the need for individual valves and multiple connections, manifold valves streamline fluid flow within hydraulic systems. This improved efficiency reduces pressure drops and minimizes energy waste, leading to cost savings and enhanced productivity.

- Reduced Potential for Leaks: The integration of multiple functions into a single manifold valve significantly reduces the number of potential leak points. This enhances the reliability and safety of hydraulic systems, as leaks can lead to downtime, increased maintenance, and potential hazards.

In conclusion, manifold valves play a vital role in hydraulic systems by providing precise control over fluid flow. Their compact design, precise control capabilities, improved efficiency, and reduced potential for leaks make them an essential component in a wide range of industrial applications. By understanding the functionality and advantages of manifold valves, operators can optimize hydraulic system performance and achieve greater productivity.