Enhancing Steelmaking Efficiency Introduction In the steelmaking process, the selection of the right materials is crucial for achieving optimal efficiency and productivity. One such material is ramming mass, which plays a vital role in the performance of induction furnaces and continuous casting machines. In this article, we will explore the types of ramming mass used […]

Continue Reading....Tag: CCM

Understanding the types of Breakout in Continuous Casting Machines

Meta TechX Engineers : Breakouts are a common occurrence in Continuous Casting Machines (CCM) used in the metal industry. These breakouts can lead to production downtime, material wastage, and safety hazards. It is crucial to understand the different types of breakouts, their possible causes, and effective ways to minimize them. In this article, we will […]

Continue Reading....CCM

Continuous casting is a process that involves the production of metal products in a continuous manner, without the need for individual casting molds for each product. This method offers several advantages over traditional casting methods. One of the main benefits of continuous casting is the ability to produce long, continuous lengths of metal products, such […]

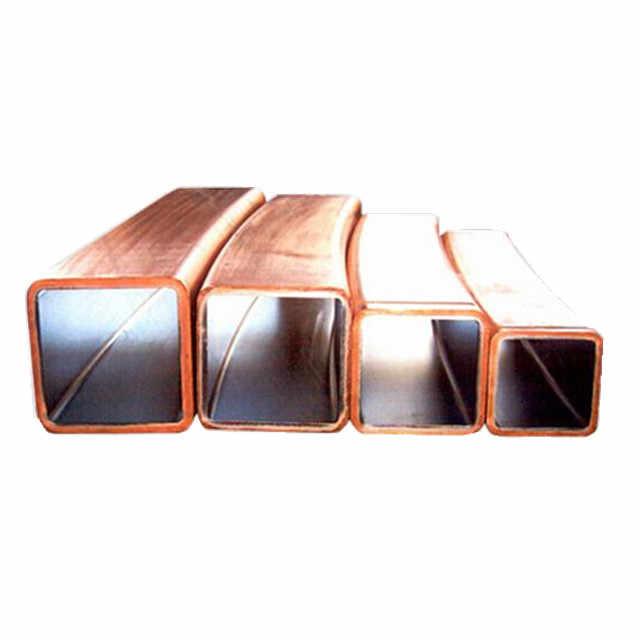

Continue Reading....Select the Right Quality of Mold Tube for CCM

Meta TechX Engineer’s Blog – When it comes to Continuous Casting Machines (CCM), selecting the right mold tube is crucial for ensuring high-quality output. The mold plays a significant role in the casting process, impacting the overall efficiency, productivity, and quality of the final product. In this article, we will discuss how to select the […]

Continue Reading....