Charge mix calculation is the process of determining the optimal combination of raw materials—like scrap, pig iron, sponge iron, and ferroalloys—to be charged into the furnace. The goal is to achieve the desired chemical composition of the molten steel while minimizing cost and energy consumption.Charge mix calculation is the unsung hero of steelmaking—where metallurgy meets […]

Continue Reading....Tag: Steel making

SOP for Induction Furnace

Standard Operating Procedure (SOP) for Induction Furnace in Steelmaking This detailed SOP covers all aspects of induction furnace operations, ensuring efficiency, safety, and consistent steel quality. 1. Objective To establish a standard procedure for operating an induction furnace in steelmaking, ensuring safe handling, efficient melting, and quality control. 2. Scope Applicable to all personnel involved […]

Continue Reading....Mechanics and Behavior of Metals

Mechanics and behavior of Metals, also known as the mechanics of materials, is a branch of mechanics that studies the behavior of solid materials under various forms of loading. This field is crucial in engineering because it helps to predict how materials will deform, break, or otherwise react under different conditions. Here are some key […]

Continue Reading....LD Converter Process in Steelmaking

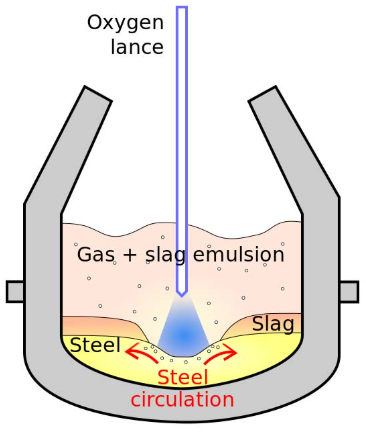

LD Process in Steelmaking: A Detailed Overview The LD (Linz-Donawitz) process, also known as the Basic Oxygen Furnace (BOF) process, is a primary steelmaking method that converts pig iron and scrap into high-quality steel. It is named after the Austrian towns of Linz and Donawitz, where it was first developed. The process relies on oxygen […]

Continue Reading....Hazard Identification and Risk Assessment in Induction Furnace

Hazard Identification and Risk Assessment (HIRA) in Induction Furnace Operations for Steel Making Induction furnaces are widely used in the steelmaking process due to their energy efficiency and ability to produce high-quality steel. However, their operation involves several hazards that require systematic identification and assessment to ensure workplace safety. Detailed explanation from MetaTechX Engineers: 1. […]

Continue Reading....Silico and Ferro Manganese in Steel Making

Silico and Ferro manganese in Steel Making Silico and ferro manganese are two types of ferroalloys used in the steelmaking process. They serve as sources of manganese, which is an essential element in steel production due to its properties that enhance the strength, hardness, and wear resistance of steel. Silico Manganese Silico manganese, an alloy […]

Continue Reading....Charge Mix and Composition in Liquid Metal

Fill all the details (Digits only) as given in the input form. Steel Melt Shop Calculator Charge Mix Calculator by Meta TechX Engineers Material Chemical Composition (%) Weight (kg) Scrap Pig Iron Sponge Iron Silico Manganese Calculate Composition Disclaimer -: This Calculator is for Educational Purpose only and has 75%+ accuracy, Which can help you […]

Continue Reading....Types of Fuels Used in Steel Industries

Steel Industries: The Fueling Powerhouses Introduction Steel is one of the most important and versatile materials known to humanity. It plays a vital role in various industries, from construction to manufacturing. The production of steel, however, is an energy-intensive process that requires a significant amount of fuel. Let’s explore with MetaTechX Engineers the different types […]

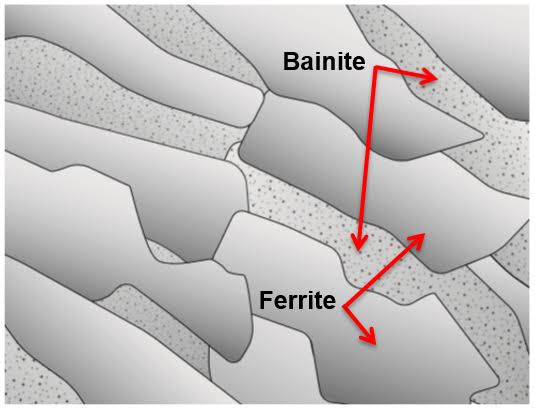

Continue Reading....Understanding the Role of Ferrite

Steel Making: Understanding the Role of Ferrite Discover the secrets of steel making and the significance of ferrite. Learn how ferrite contributes to steel’s ductility, toughness, and magnetic properties. Explore FAQs about ferrite in steel Introduction with Meta TechX Engineers: Discover the secrets of steel making and the significance of ferrite. Learn how ferrite contributes […]

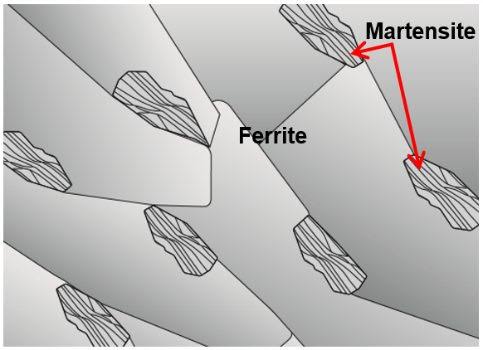

Continue Reading....Understanding the Power of Martensite in Steel

The Fascinating Process of Steel Making: Understanding Martensite Formation Introduction with Meta TechX Engineers: The Essence of Steel Making Every day, we encounter numerous products made of steel, from household appliances to towering skyscrapers. But have you ever wondered how steel is produced and what gives it its remarkable strength? In the world of metallurgy, […]

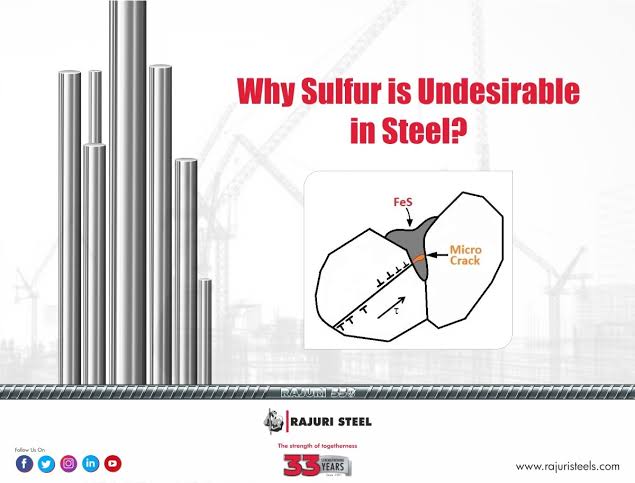

Continue Reading....Understanding the Impact of Sulphur on Steel Quality

Introduction with Meta TechX Engineers The Role of Sulphur in Steel Making Steel, a vital material in the modern world, is known for its strength, durability, and versatility. However, the quality of steel can be significantly influenced by various factors, including the presence of impurities. One such impurity, sulphur, plays a crucial role in the […]

Continue Reading....Explore the basic understanding of Iron and Carbon diagram

An In-Depth Guide to Iron and Carbon Diagram Introduction with Meta TechX Engineers Steel making is a complex process that involves the manipulation of iron and carbon to create a material that is strong, durable, and versatile. This article will delve into the world of steel making, exploring the iron and carbon diagram, which is […]

Continue Reading....Understanding the Differences Between Inductotherm and Megatherm Induction Furnaces

Meta TechX Engineers : When it comes to melting metals, induction furnaces have become the go-to choice for many industries. These furnaces offer efficient and precise heating, making them ideal for a variety of applications. One crucial aspect of an induction furnace is its crucible design, as it directly impacts the melting process. In this […]

Continue Reading....Advantages and Limitations of Neutral Ramming Mass in Induction Furnace

Introduction In the realm of steel making, the use of quality refractory materials is paramount for ensuring efficient and cost-effective production. One such material is Neutral Ramming Mass, a specially formulated lining material used in induction furnaces. In this article, we will explore what Neutral Ramming Mass is, how it is made, and delve into […]

Continue Reading....Advantages and Limitations of Acidic Ramming Mass in Induction Furnace

Introduction In the vast realm of steelmaking, acidic Ramming Mass plays an indispensable role. This exceptional material is used in induction furnaces to line the inner walls and protect them from the harsh conditions of intense heat and chemical reactions. It not only ensures the longevity of the furnace but also contributes to the production […]

Continue Reading....Advantage and Limitations of Basic Ramming Mass in Induction Furnace

Introduction In the world of steel making, there are various key components that play a critical role in ensuring the production of high-quality steel. One such component is the basic ramming mass used in induction furnaces. This article will delve into the basics of basic ramming mass, its production process, as well as its advantages […]

Continue Reading....Quality of Ramming Mass in Induction Furnace and CCM

Enhancing Steelmaking Efficiency Introduction In the steelmaking process, the selection of the right materials is crucial for achieving optimal efficiency and productivity. One such material is ramming mass, which plays a vital role in the performance of induction furnaces and continuous casting machines. In this article, we will explore the types of ramming mass used […]

Continue Reading....Preventive Measures and Possible Causes for Induction Crucible Leakage

Introduction: Induction crucibles are essential components in various industrial processes, including metal melting and casting. However, one common issue faced by operators is the leakage of induction crucibles. This article aims to provide step-by-step preventive measures to avoid leakage and shed light on the potential reasons behind such occurrences. By implementing these strategies, operators can […]

Continue Reading....Steel Making Practice in Induction Furnace, A Step-by-Step Guide

Introduction Are you interested in learning about the intricate process of steel making in an induction furnace? Look no further, as this comprehensive guide will walk you through the step-by-step practice of producing high-quality steel using induction furnaces. From understanding the parameters to following the best practices, this article will provide you with the expertise […]

Continue Reading....Explore the step by step process of Lining an induction furnace

Introduction Are you familiar with the lining process and parameters of an induction furnace? In this article, we will walk you through the step by step process of lining an induction furnace, along with the necessary parameters to ensure its efficient operation. The lining of an induction furnace plays a crucial role in its performance […]

Continue Reading....Understanding the types of Breakout in Continuous Casting Machines

Meta TechX Engineers : Breakouts are a common occurrence in Continuous Casting Machines (CCM) used in the metal industry. These breakouts can lead to production downtime, material wastage, and safety hazards. It is crucial to understand the different types of breakouts, their possible causes, and effective ways to minimize them. In this article, we will […]

Continue Reading....Comparative Analysis of Aluminum Killed Steel and Silicon Killed Steel

Meta TechX Engineer’s Blog –Aluminum killed steel and Silicon killed steel are two commonly used types of steel. These variations of steel differ in composition and properties, which ultimately impact their advantages and disadvantages in different applications. This article will explore the specifics of aluminum killed steel and silicon killed steel, delving into their benefits […]

Continue Reading....Continuous Casting Preparation

Preparing a continuous casting machine before starting the process is crucial to ensure the production of high-quality castings. Here is a step-by-step guide on how to prepare a continuous casting machine: Join Us For Updates Step 1: Inspection and Maintenance – Thoroughly inspect the continuous casting machine and its components for any signs of damage, […]

Continue Reading....CCM

Continuous casting is a process that involves the production of metal products in a continuous manner, without the need for individual casting molds for each product. This method offers several advantages over traditional casting methods. One of the main benefits of continuous casting is the ability to produce long, continuous lengths of metal products, such […]

Continue Reading....CPC- Calcined Petroleum Coke

Calcined Petroleum Coke (CPC) is an indispensable component in the steelmaking industry. Its primary function is to serve as a carbon additive, effectively increasing the carbon content of molten iron. This essential role not only helps to reduce impurities but also contributes to the overall enhancement of steel quality. By introducing Calcined Petroleum Coke into […]

Continue Reading....Induction Furnace in Steel Making

Meta TechX Engineers – An Electric induction furnace is a type of furnace used for melting metal and creating various metal products. It is widely utilized in the manufacturing industry due to its efficiency, precision, and versatility. Induction furnaces use electromagnetic induction to generate heat, resulting in a controlled and energy-efficient melting process. The principle […]

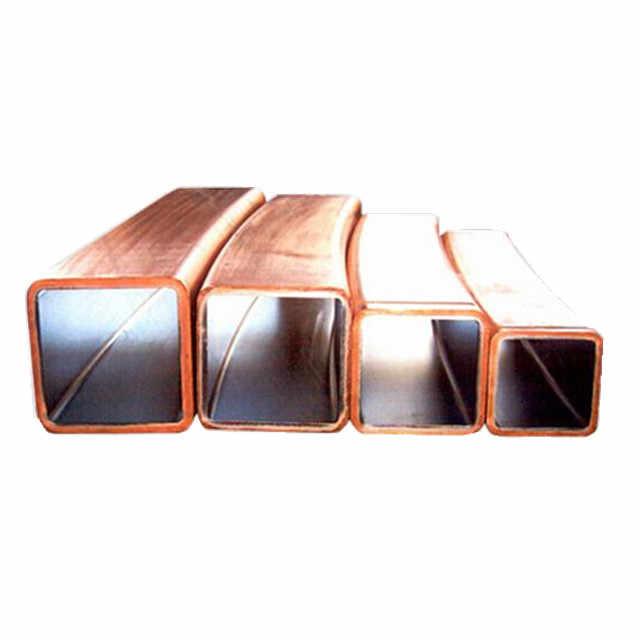

Continue Reading....Select the Right Quality of Mold Tube for CCM

Meta TechX Engineer’s Blog – When it comes to Continuous Casting Machines (CCM), selecting the right mold tube is crucial for ensuring high-quality output. The mold plays a significant role in the casting process, impacting the overall efficiency, productivity, and quality of the final product. In this article, we will discuss how to select the […]

Continue Reading....Advantage and Disadvantage of Silicon Content in Steel

Silicon in Steel Making… Silicon plays an impotent role in the steelmaking process, as it reacts with oxygen and other impurities in the molten steel. This reaction forms silicon dioxide, a compound that rises to the surface, allowing it to be easily removed. By removing the impurities, silicon helps improve the quality of the steel. […]

Continue Reading....