Discover the significance of tensile strength in hot rolled products. Learn how it influences the performance and reliability of various industrial applications. Meta TechX Engineers

Understanding Tensile Strength in Hot Rolled Products

Introduction:

Hot rolled products are widely used in various industries due to their superior mechanical properties. One of the important characteristics to consider while evaluating hot rolled products is their tensile strength. In this article, we will delve into what exactly tensile strength is, and why it is crucial in the context of hot rolled products. Meta Blogs for Steel industry professionals.

What is Tensile Strength?

Tensile strength is a measure of a material’s resistance to breaking under tension. It denotes the maximum stress a material can withstand before it fractures or fails. This property is essential for evaluating the durability and performance of structural components, especially those subjected to significant loads.

Why is Tensile Strength Important in Hot Rolled Products?

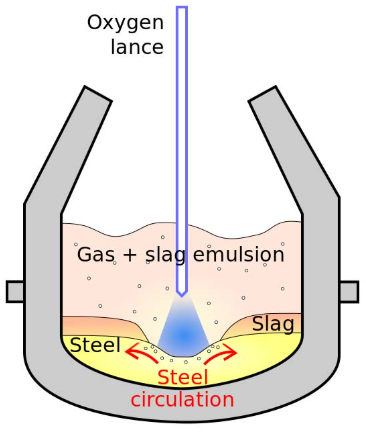

In the realm of hot rolled products, tensile strength plays a vital role in determining their structural integrity and overall reliability. When materials are processed through the hot rolling technique, they undergo plastic deformation, resulting in changes in their microstructure. This process imparts certain mechanical properties to the material, including tensile strength.

The Impact of Tensile Strength on Structural Stability

Hot rolled products with high tensile strength offer improved structural stability, making them suitable for applications where load-bearing capabilities are crucial. For instance, in the construction industry, beams and columns made from high tensile strength hot rolled steel ensure the stability and safety of multi-story buildings.

How Tensile Strength Impacts Manufacturing Processes

Tensile strength also influences several manufacturing processes. For example, materials with low tensile strength are prone to breakage, which can hamper the efficiency of manufacturing operations. Conversely, materials with optimal tensile strength can be shaped and formed into desired configurations without compromising their structural integrity.

Determining Tensile Strength in Hot Rolled Products

To ascertain the tensile strength of hot rolled products, various testing methods are employed, such as the tensile test or the pull test. This test involves subjecting a sample of the material to an increasing tensile force until it fractures. The force required to cause the fracture is then measured and used to calculate the material’s tensile strength.

Factors Influencing Tensile Strength in Hot Rolled Products

Several factors affect the tensile strength of hot rolled products, including the chemical composition, grain size, and heat treatment. Alloying elements such as carbon, manganese, and silicon are often added to enhance the material’s mechanical properties, including tensile strength. Additionally, the control of cooling rates during the hot rolling process can significantly impact the final tensile strength.

Conclusion

Tensile strength is a vital parameter to consider when evaluating the suitability of hot rolled products for various applications. High tensile strength ensures structural stability, reliable performance, and efficient manufacturing processes. By understanding the significance of tensile strength in hot rolled products, manufacturers and engineers can make informed decisions regarding material selection, resulting in improved product quality and overall project success.