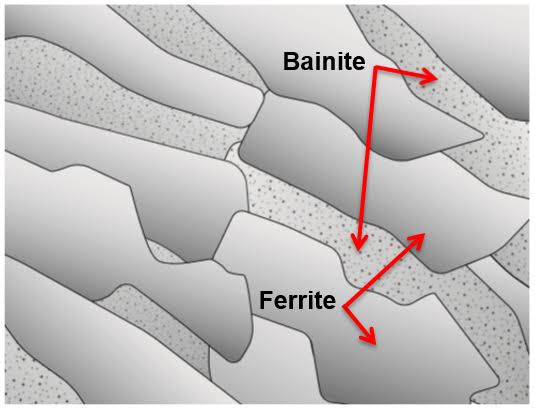

Steel Making: Understanding the Role of Ferrite Discover the secrets of steel making and the significance of ferrite. Learn how ferrite contributes to steel’s ductility, toughness, and magnetic properties. Explore FAQs about ferrite in steel Introduction with Meta TechX Engineers: Discover the secrets of steel making and the significance of ferrite. Learn how ferrite contributes […]

Continue Reading....Month: December 2023

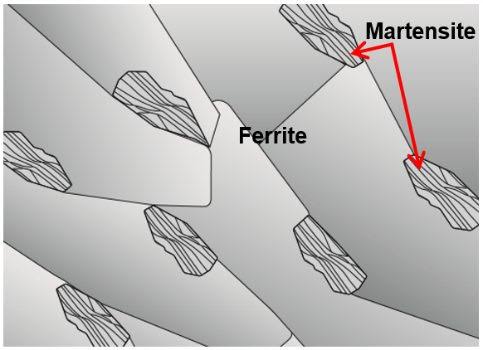

Understanding the Power of Martensite in Steel

The Fascinating Process of Steel Making: Understanding Martensite Formation Introduction with Meta TechX Engineers: The Essence of Steel Making Every day, we encounter numerous products made of steel, from household appliances to towering skyscrapers. But have you ever wondered how steel is produced and what gives it its remarkable strength? In the world of metallurgy, […]

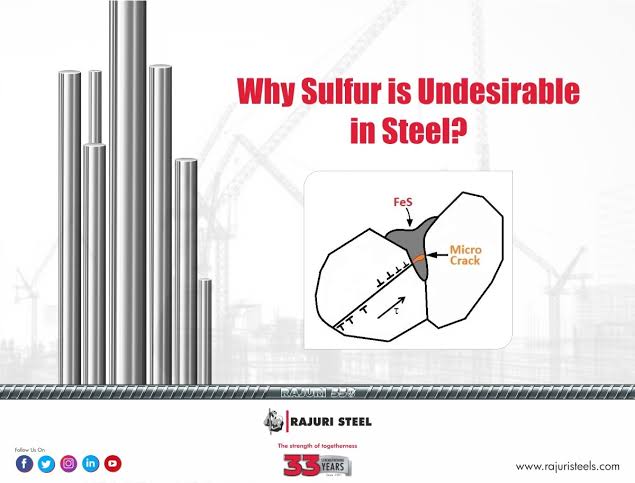

Continue Reading....Understanding the Impact of Sulphur on Steel Quality

Introduction with Meta TechX Engineers The Role of Sulphur in Steel Making Steel, a vital material in the modern world, is known for its strength, durability, and versatility. However, the quality of steel can be significantly influenced by various factors, including the presence of impurities. One such impurity, sulphur, plays a crucial role in the […]

Continue Reading....Explore the basic understanding of Iron and Carbon diagram

An In-Depth Guide to Iron and Carbon Diagram Introduction with Meta TechX Engineers Steel making is a complex process that involves the manipulation of iron and carbon to create a material that is strong, durable, and versatile. This article will delve into the world of steel making, exploring the iron and carbon diagram, which is […]

Continue Reading....Understanding the Differences Between Inductotherm and Megatherm Induction Furnaces

Meta TechX Engineers : When it comes to melting metals, induction furnaces have become the go-to choice for many industries. These furnaces offer efficient and precise heating, making them ideal for a variety of applications. One crucial aspect of an induction furnace is its crucible design, as it directly impacts the melting process. In this […]

Continue Reading....Advantages and Limitations of Neutral Ramming Mass in Induction Furnace

Introduction In the realm of steel making, the use of quality refractory materials is paramount for ensuring efficient and cost-effective production. One such material is Neutral Ramming Mass, a specially formulated lining material used in induction furnaces. In this article, we will explore what Neutral Ramming Mass is, how it is made, and delve into […]

Continue Reading....Advantages and Limitations of Acidic Ramming Mass in Induction Furnace

Introduction In the vast realm of steelmaking, acidic Ramming Mass plays an indispensable role. This exceptional material is used in induction furnaces to line the inner walls and protect them from the harsh conditions of intense heat and chemical reactions. It not only ensures the longevity of the furnace but also contributes to the production […]

Continue Reading....Magnesia and Sintered magnesia and their unique properties

Meta TechX Engineers : Learn about the differences between magnesia and sintered magnesia, their unique properties, and a range of applications. Discover which material is ideal for specific industrial needs. Magnesia and sintered magnesia are widely used materials in various industries due to their unique properties and applications. In this article, we will delve into […]

Continue Reading....Advantage and Limitations of Basic Ramming Mass in Induction Furnace

Introduction In the world of steel making, there are various key components that play a critical role in ensuring the production of high-quality steel. One such component is the basic ramming mass used in induction furnaces. This article will delve into the basics of basic ramming mass, its production process, as well as its advantages […]

Continue Reading....Quality of Ramming Mass in Induction Furnace and CCM

Enhancing Steelmaking Efficiency Introduction In the steelmaking process, the selection of the right materials is crucial for achieving optimal efficiency and productivity. One such material is ramming mass, which plays a vital role in the performance of induction furnaces and continuous casting machines. In this article, we will explore the types of ramming mass used […]

Continue Reading....Preventive Measures and Possible Causes for Induction Crucible Leakage

Introduction: Induction crucibles are essential components in various industrial processes, including metal melting and casting. However, one common issue faced by operators is the leakage of induction crucibles. This article aims to provide step-by-step preventive measures to avoid leakage and shed light on the potential reasons behind such occurrences. By implementing these strategies, operators can […]

Continue Reading....Steel Making Practice in Induction Furnace, A Step-by-Step Guide

Introduction Are you interested in learning about the intricate process of steel making in an induction furnace? Look no further, as this comprehensive guide will walk you through the step-by-step practice of producing high-quality steel using induction furnaces. From understanding the parameters to following the best practices, this article will provide you with the expertise […]

Continue Reading....Explore the step by step process of Lining an induction furnace

Introduction Are you familiar with the lining process and parameters of an induction furnace? In this article, we will walk you through the step by step process of lining an induction furnace, along with the necessary parameters to ensure its efficient operation. The lining of an induction furnace plays a crucial role in its performance […]

Continue Reading....A Complete Guide to TPM in the Hot Rolling Process

Meta TechX Engineers: In the world of manufacturing and industrial processes, TPM stands for Total Productive Maintenance. It is a method that focuses on the proactive and planned maintenance of machinery and equipment. TPM aims to maximize productivity, reduce downtime, and improve the overall efficiency of the production process. In this article, we will explore […]

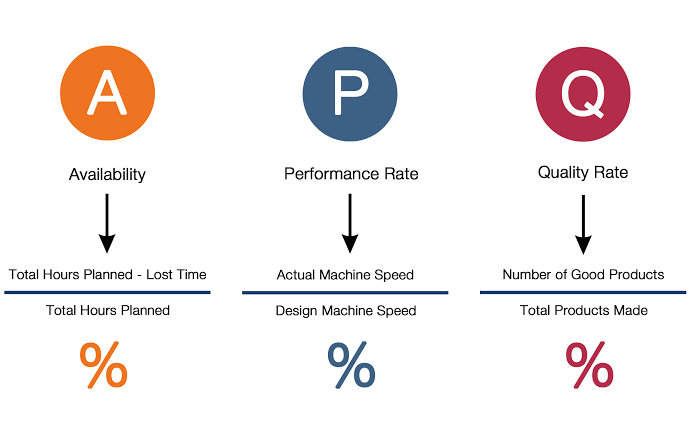

Continue Reading....Lession About Overall Equipment Efficiency and it’s Advantages

Meta TechX Engineers : In today’s rapidly evolving industrial landscape, optimizing efficiency and performance is of paramount importance for businesses. One key metric that helps manufacturers gauge their equipment’s effectiveness is Overall Equipment Efficiency (OEE). This article will delve into the concept of OEE, how to calculate it, and offer valuable insights on maintaining equipment […]

Continue Reading....Calculation for Actual Draft and Speed Adjustment

Hot rolling process Speed Adjustment…

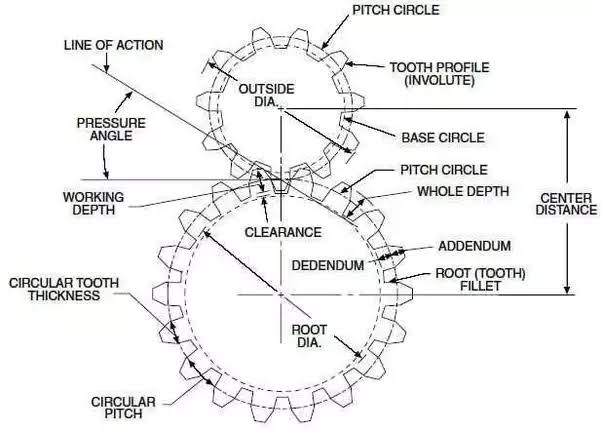

Continue Reading....Basic concepts of Designing Gears for Hot Rolling Mills

Meta TechX Engineers: Learn how to design gears for hot rolling mills using the required parameters, formulas, and essential insights from industry professionals. Discover the key factors that contribute to successful gear design in this in-depth article.Introduction:Designing gears for hot rolling mills requires meticulous attention to detail, expertise, and an understanding of the parameters and […]

Continue Reading....What is Module in Designing Gears

Meta TechX Engineers: In the vast field of mechanical engineering, gears play a crucial role in transmitting motion and power between two or more rotating shafts. The design of gears has evolved over the years, leading to the development of advanced techniques that optimize their efficiency and performance. One such technique is the implementation of […]

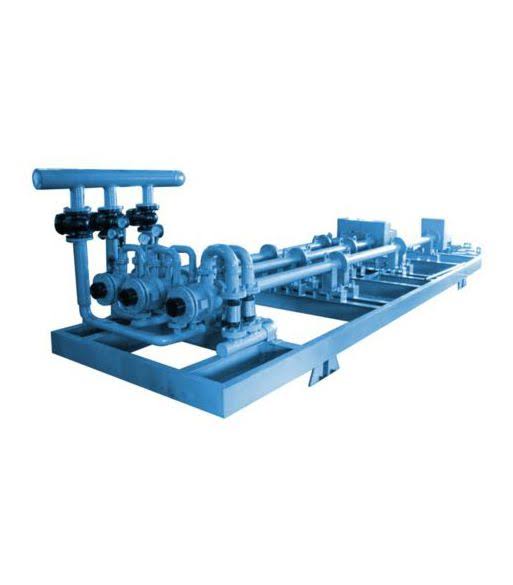

Continue Reading....Automatic Flow and Pressure Control Systems for Quenching Box

Meta TechX Engineers -: Discover the importance of automatic flow pressure control systems for quenching boxes. Learn how they enhance precision, increase productivity, and improve overall efficiency in the manufacturing process. In the world of industrial manufacturing, maintaining precise control over the quenching process is essential to ensure the desired outcomes of heat treatment. One […]

Continue Reading....Understanding the types of Breakout in Continuous Casting Machines

Meta TechX Engineers : Breakouts are a common occurrence in Continuous Casting Machines (CCM) used in the metal industry. These breakouts can lead to production downtime, material wastage, and safety hazards. It is crucial to understand the different types of breakouts, their possible causes, and effective ways to minimize them. In this article, we will […]

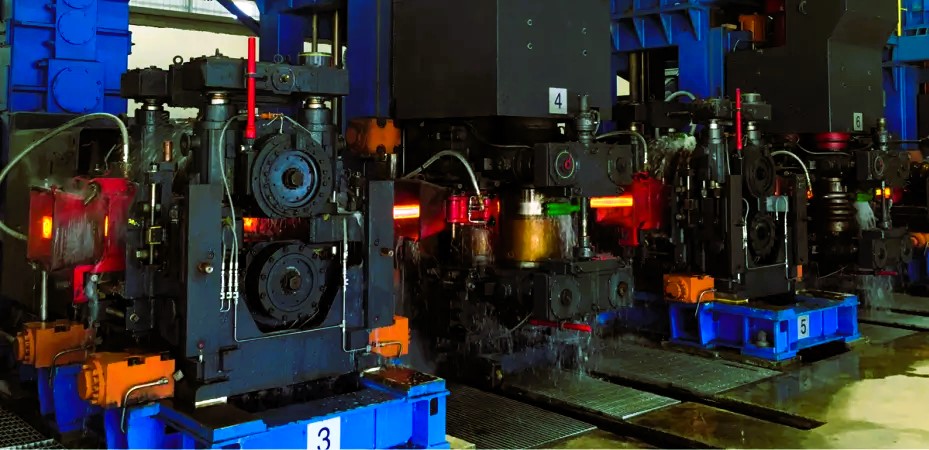

Continue Reading....Hot Rolling of Strip – Process, Parameters and Quality Defects

Strip Rolling in Hot Rolling Process: A in-short Overview by Meta TechX Engineers Introduction -: Strip rolling is a crucial step in the hot rolling process, which involves transforming metal Billets or Slabs into thin strips of various dimensions. Meta TechX Engineers aims to provide a comprehensive understanding of strip rolling, from the initial steps […]

Continue Reading....MPC Control Systems in Hot Rolling Mills Improving Efficiency and Quality

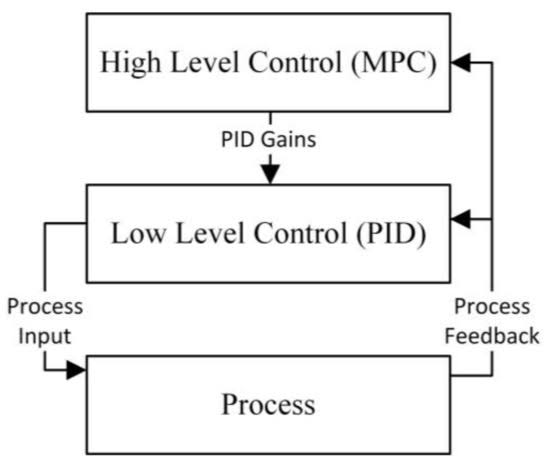

Introduction: Hot rolling mills operate under extreme conditions, including high temperatures and heavy loads. To optimize the performance and productivity of hot rolling mills, the implementation of model predictive control (MPC) systems has gained significant importance. In this article, we will explore the process of implementing MPC control in hot rolling mills and understand how […]

Continue Reading....What is Automatic Gauge Control System in Hot Rolling Mill

Introduction Hot rolling mills play a crucial role in the steel production process, shaping solid metal into various forms. To ensure the precise thickness of the rolled metal, manufacturers rely on advanced technology known as a Gauge Control System. In this article, we delve into the world of Gauge Control Systems, exploring how they work, […]

Continue Reading....The Major Control Systems in Hot Rolling Mill

Introduction -: Hot rolling mills are crucial in the manufacturing industry for processing metals such as steel and aluminum. These mills shape and deform metals at high temperatures to produce various products, including sheets, plates, and rods. To ensure smooth operations and quality output, hot rolling mills employ various control systems. In this article, we […]

Continue Reading....Implementing PID Control in Hot Rolling Mills for Enhanced Performance

To ensure precise control over the complex Hot rolling process, advanced control systems like Proportional-Integral-Derivative (PID) control are employed. In this article, we will dive into the process of implementing PID control in a hot rolling mill, exploring its key features and benefits. What is PID Control? PID control is a widely used feedback control […]

Continue Reading....Advance control system PID and MPC in Hot Rolling Mill

Introduction : Hot rolling mills employ advanced control systems to ensure efficient and precise operations. Among the various control techniques, proportional-integral-derivative (PID) control and model predictive control (MPC) play significant roles in optimizing the hot rolling process. Let’s take a closer look at these control strategies and how they are utilized in hot rolling mills. […]

Continue Reading....Tension Control System Ensuring Efficiency and Quality

Introduction : Tension control system in Hot Rolling process, which ensures the proper tension levels are maintained throughout the rolling operation. In this article, we will delve into the intricacies of the tension control system in hot rolling mills and explore its working principles, required parameters, and algorithms. What is a Tension Control System in […]

Continue Reading....Solenoid Control Relief Valve and it’s Advantages in Hydraulic Systems

Meta TechX Engineers : In hydraulic systems, the solenoid control relief valve plays a crucial role. But what exactly is a solenoid control relief valve and how does it operate? In this article, we will delve into the details of this essential component, exploring its functions and benefits. What is a Solenoid Control Relief Valve? […]

Continue Reading....Manifold it’s components, Operations and Advantages in Hydraulic Systems

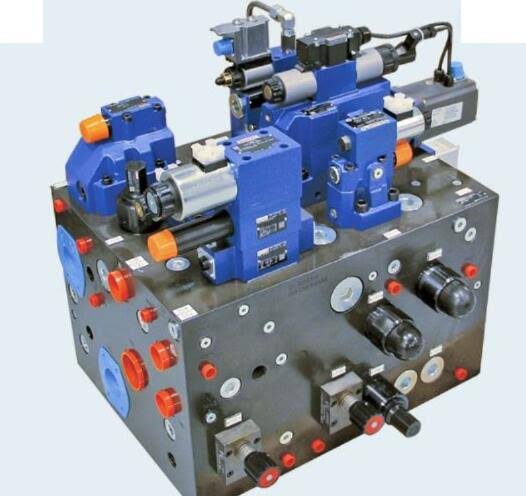

Meta TechX Engineers: When it comes to hydraulic systems, manifold valves play a crucial role in ensuring efficient and precise control over fluid flow. But what exactly is a manifold valve in hydraulic systems, how does it operate, and what are its components and advantages? In this article, we will dive deep into the world […]

Continue Reading....How to Select Right Refractory Bricks for Reheating Furnace

Meta TechX Engineers – In the process of selecting refractory bricks for your reheating furnace. Choosing the right refractory bricks is crucial for the efficient operation of your reheating furnace. In this article, we will guide you through the process of selecting the most suitable refractory bricks for your specific needs. Let’s dive in!Why are […]

Continue Reading....