How to Improve Yield Stress in Hot Rolled Products?

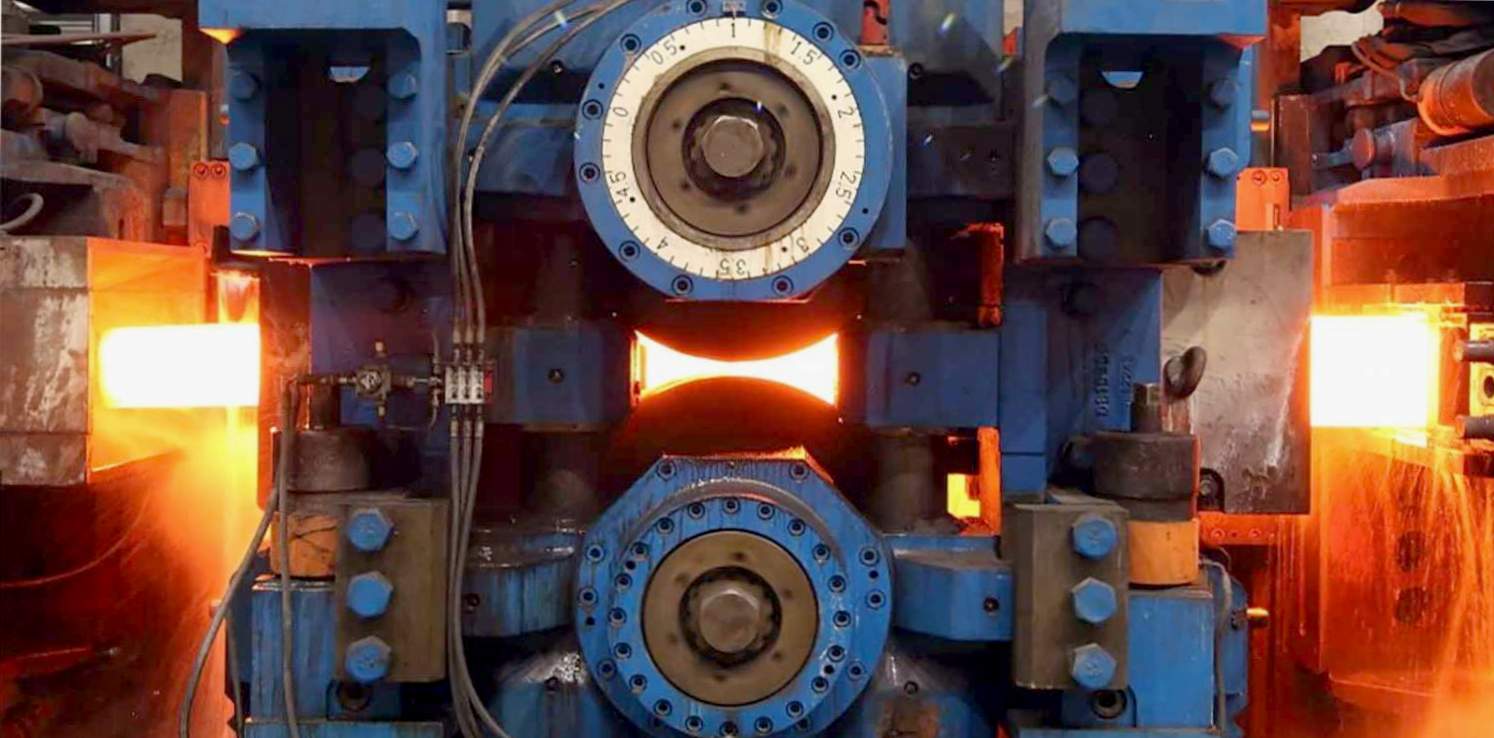

Introduction:

When it comes to hot rolled products, one of the most important properties to consider is yield stress. Yield stress refers to the amount of stress a material can withstand before it begins to deform permanently. In the context of hot rolled products, higher yield stress translates to increased strength, durability, and resistance to deformation. As an expert in the field, I will delve into some effective strategies to improve yield stress in hot rolled products and enhance their performance. Meta Blogs

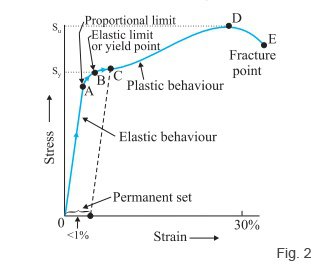

Understanding Yield Stress:

Before discussing techniques to improve yield stress, it is crucial to have a clear understanding of what it entails. The yield stress of a material is the point at which it transitions from elastic behavior to plastic behavior. In other words, it is the stress required to induce permanent deformation. The goal is to maximize this threshold so that the material remains resilient and maintains its structural integrity under significant loads.

Material Selection:

Choosing the right material is the first and foremost step in improving yield stress in hot rolled products. Various alloys and compositions exhibit different yield stress characteristics. Steels with higher carbon content, for example, tend to have increased yield stress due to the formation of stronger carbide bonds within the microstructure. By carefully selecting the appropriate material based on the desired yield stress requirements, manufacturers can lay the foundation for improved product performance.

Heat Treatment:

Heat treatment is an indispensable process in optimizing the mechanical properties of hot rolled products. Quenching and tempering, for instance, can significantly enhance yield stress. Quenching involves rapid cooling of the material from a high temperature, leading to the formation of a hardened structure. Subsequent tempering, which involves heating the material to a moderate temperature, helps relieve internal stresses and improve ductility without compromising the yield stress.

Alloying Elements:

Introducing alloying elements during the manufacturing process (Steel Making) can lead to a considerable improvement in yield stress. Elements such as manganese, silicon, and vanadium can form solid solutions or precipitates, which strengthen the material and elevate its yield stress. Additionally, alloying elements can refine the grain structure, reducing the likelihood of deformation and increasing overall strength.

Cold Working:

Cold working techniques, such as rolling or drawing, are often employed to improve the yield stress of hot rolled products. By subjecting the material to plastic deformation at room temperature, dislocations are introduced, enhancing the material’s strength and yield stress. Cold working also leads to a more refined grain structure, further improving the material’s performance under load.

Surface Treatment:

Another way to improve yield stress is through surface treatments. Shot peening, for instance, involves bombarding the material’s surface with small, high-velocity projectiles. This process induces compressive stress on the surface, leading to an increased yield stress and improved fatigue resistance. Surface coatings, such as plating or nitriding, can also provide a protective layer and enhance the material’s yield stress characteristics.

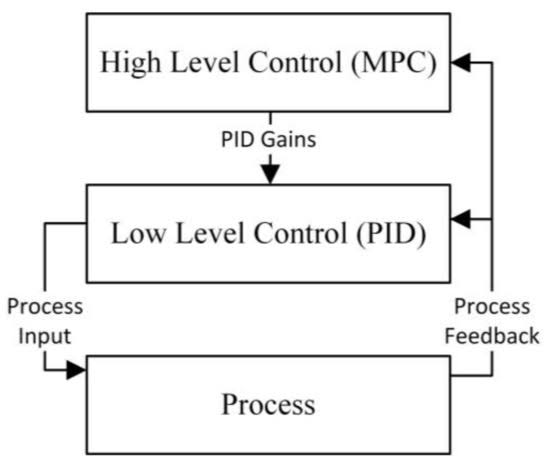

Quality Control:

Implementing stringent quality control measures is vital in ensuring that hot rolled products consistently meet the desired yield stress specifications. Regular testing and inspection throughout the production process can help identify any deviations or inconsistencies that may impact yield stress. By maintaining strict quality control standards, manufacturers can have confidence in the integrity and performance of their products.

Conclusion:

Improving yield stress in hot rolled products is crucial for maximizing strength, resilience, and overall product performance. Careful material selection, appropriate heat treatment, alloying elements, cold working, surface treatments, and quality control measures are all essential factors that contribute to enhancing yield stress. By implementing these strategies, manufacturers can confidently produce high-quality hot rolled products that meet stringent industry standards and customer expectations.