Art of Designing Rolling Passes in Hot Rolling Process with Meta TechX Engineers

Understanding the Hot Rolling Process

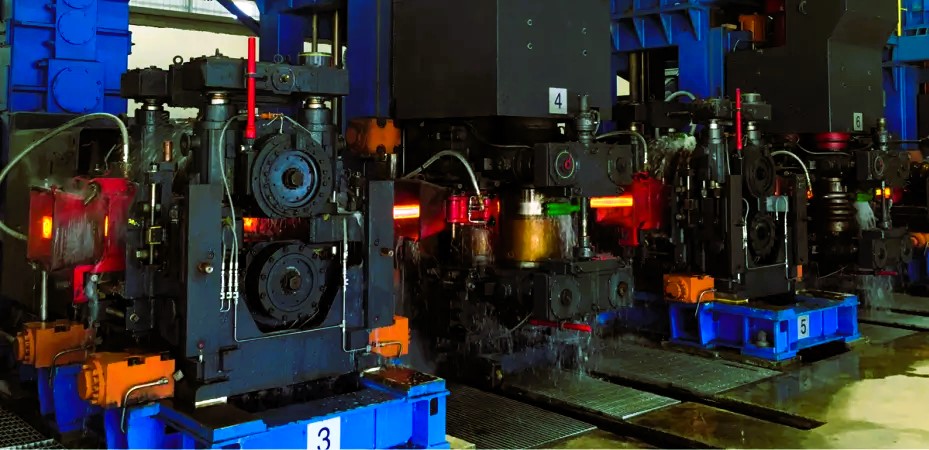

In the world of metalworking, the hot rolling process is a crucial method for shaping metals into various forms. This process involves subjecting metal ingots or billets to high temperatures and passing them through a series of rollers to achieve the desired shape and dimensions. An essential aspect of the hot rolling process is the design of rolling passes, which plays a significant role in determining the quality and efficiency of the final product.

The Significance of Rolling Passes

Rolling passes are the specific sequences through which the metal is passed during the hot rolling process. Each pass serves a unique purpose in gradually reducing the thickness and altering the shape of the metal. Proper design of rolling passes is critical for ensuring uniform deformation, minimizing defects, and achieving the desired mechanical properties in the final product.

A- Factors Influencing Rolling Pass Design

1-Material Properties

The material being rolled has a significant impact on the design of rolling passes. Factors such as the metal’s composition, grain structure, and mechanical properties must be considered to determine the optimal pass sequence and parameters.

2-Desired End Product

The final dimensions, surface finish, and mechanical properties required for the end product influence the design of rolling passes. Different products may require specific pass sequences to achieve the desired characteristics.

3-Equipment Capabilities

The capabilities of the rolling mill, including the number of stands, roll diameter, and rolling speed, directly influence the design of rolling passes. Understanding the limitations and capabilities of the equipment is vital for efficient pass design.

B- Designing an Effective Pass Sequence

1-Initial Passes

The initial rolling passes aim to reduce the thickness of the metal while maintaining a uniform cross-section. These passes typically require higher reduction rates and may involve roughing stands to achieve significant thickness reduction.

2-Intermediate Passes

Intermediate passes focus on further reducing the thickness and imparting specific deformation characteristics to the metal. These passes may involve adjusting the temperature and applying different roll configurations to achieve the desired shape and properties.

3-Final Passes

The final rolling passes are crucial for achieving the desired dimensional accuracy, surface finish, and mechanical properties. Careful consideration of the pass parameters, such as roll gap, roll speed, and temperature, is essential to ensure the quality of the final product.

4-Ensuring Optimal Pass Design

Achieving an optimal design for rolling passes requires a comprehensive understanding of the material, process, and equipment involved. It involves a balance of theoretical knowledge, practical experience, and continuous improvement to fine-tune the pass sequence for specific products and materials.

In conclusion, the design of rolling passes in the hot rolling process is a complex and critical aspect of metal production. By considering material properties, desired end product characteristics, and equipment capabilities, manufacturers can optimize pass designs to achieve high-quality, dimensionally accurate products with the desired mechanical properties. Mastering the art of designing rolling passes is essential for ensuring efficiency and excellence in the hot rolling process.