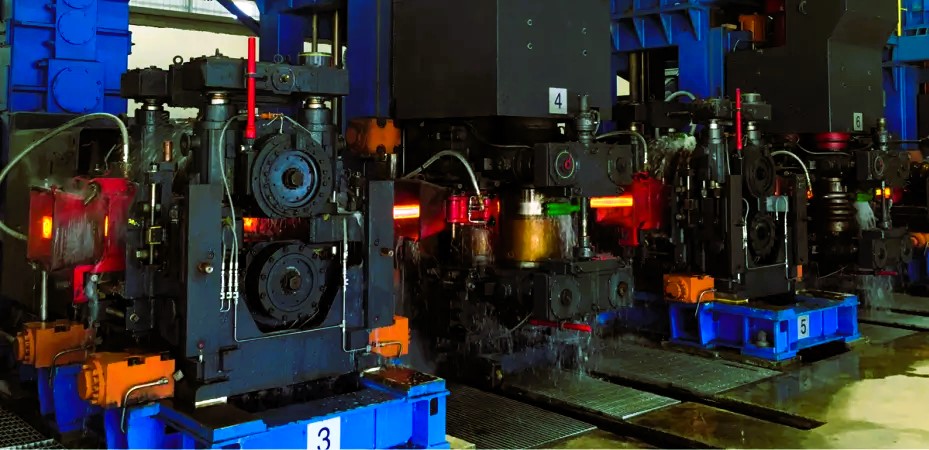

Introduction: Hot rolling mills operate under extreme conditions, including high temperatures and heavy loads. To optimize the performance and productivity of hot rolling mills, the implementation of model predictive control (MPC) systems has gained significant importance. In this article, we will explore the process of implementing MPC control in hot rolling mills and understand how […]

Continue Reading....Tag: Control systems

What is Automatic Gauge Control System in Hot Rolling Mill

Introduction Hot rolling mills play a crucial role in the steel production process, shaping solid metal into various forms. To ensure the precise thickness of the rolled metal, manufacturers rely on advanced technology known as a Gauge Control System. In this article, we delve into the world of Gauge Control Systems, exploring how they work, […]

Continue Reading....The Major Control Systems in Hot Rolling Mill

Introduction -: Hot rolling mills are crucial in the manufacturing industry for processing metals such as steel and aluminum. These mills shape and deform metals at high temperatures to produce various products, including sheets, plates, and rods. To ensure smooth operations and quality output, hot rolling mills employ various control systems. In this article, we […]

Continue Reading....Implementing PID Control in Hot Rolling Mills for Enhanced Performance

To ensure precise control over the complex Hot rolling process, advanced control systems like Proportional-Integral-Derivative (PID) control are employed. In this article, we will dive into the process of implementing PID control in a hot rolling mill, exploring its key features and benefits. What is PID Control? PID control is a widely used feedback control […]

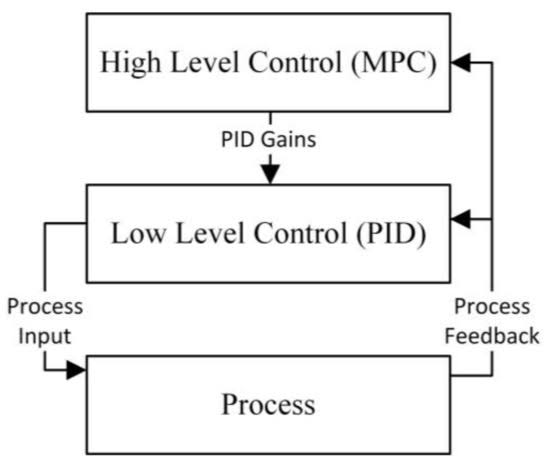

Continue Reading....Advance control system PID and MPC in Hot Rolling Mill

Introduction : Hot rolling mills employ advanced control systems to ensure efficient and precise operations. Among the various control techniques, proportional-integral-derivative (PID) control and model predictive control (MPC) play significant roles in optimizing the hot rolling process. Let’s take a closer look at these control strategies and how they are utilized in hot rolling mills. […]

Continue Reading....Tension Control System Ensuring Efficiency and Quality

Introduction : Tension control system in Hot Rolling process, which ensures the proper tension levels are maintained throughout the rolling operation. In this article, we will delve into the intricacies of the tension control system in hot rolling mills and explore its working principles, required parameters, and algorithms. What is a Tension Control System in […]

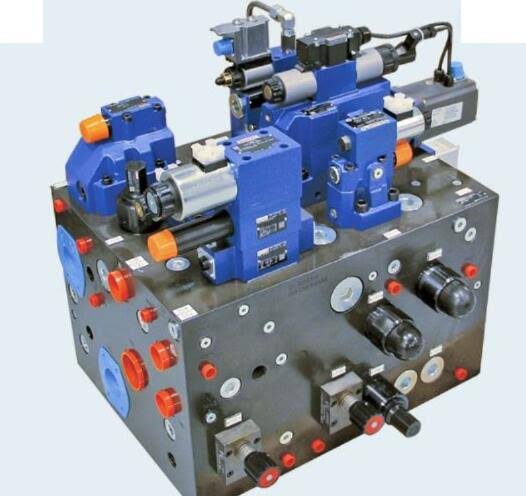

Continue Reading....Manifold it’s components, Operations and Advantages in Hydraulic Systems

Meta TechX Engineers: When it comes to hydraulic systems, manifold valves play a crucial role in ensuring efficient and precise control over fluid flow. But what exactly is a manifold valve in hydraulic systems, how does it operate, and what are its components and advantages? In this article, we will dive deep into the world […]

Continue Reading....