Mechanics and behavior of Metals, also known as the mechanics of materials, is a branch of mechanics that studies the behavior of solid materials under various forms of loading. This field is crucial in engineering because it helps to predict how materials will deform, break, or otherwise react under different conditions. Here are some key […]

Continue Reading....Tag: Hot Rolling Mill

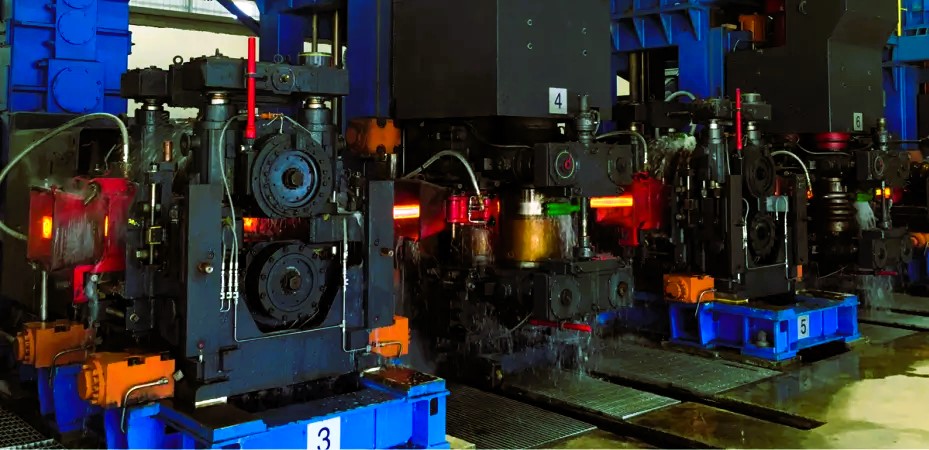

Enhancing the lifespan of work rolls in a hot rolling mill

Enhancing the lifespan of work rolls in a hot rolling mill is crucial for improving productivity, reducing maintenance costs, and ensuring consistent product quality. Several key criteria should be considered to achieve this goal: By addressing these major criteria and implementing best practices, hot rolling mills can enhance the lifespan of work rolls, leading to […]

Continue Reading....Performance analysis of a hot rolling mill

Analyzing the performance of a hot rolling mill to improve productivity and reduce production costs and scrap value involves various factors including efficiency, yield, downtime, and quality control. Let’s break down the process and considerations: By analyzing these factors and identifying areas for improvement, such as reducing downtime, minimizing scrap, and optimizing processes, the overall […]

Continue Reading....Hot Rolling Calculator

Hot Rolling Calculator Hot Rolling Calculator by Prashant Goswami CTO MetaTechX Roll Diameter (mm): Initial Thickness (mm): Initial Width (mm): Final Thickness (mm): Final Width (mm): Motor RPM: Gear Ratio: Calculate Results:

Continue Reading....A Complete Guide to TPM in the Hot Rolling Process

Meta TechX Engineers: In the world of manufacturing and industrial processes, TPM stands for Total Productive Maintenance. It is a method that focuses on the proactive and planned maintenance of machinery and equipment. TPM aims to maximize productivity, reduce downtime, and improve the overall efficiency of the production process. In this article, we will explore […]

Continue Reading....Calculation for Actual Draft and Speed Adjustment

Hot rolling process Speed Adjustment…

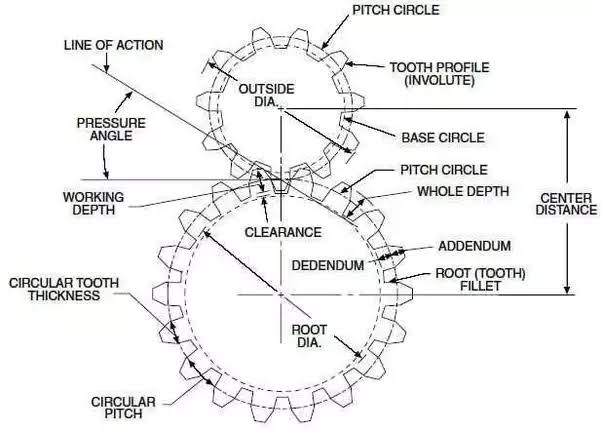

Continue Reading....Basic concepts of Designing Gears for Hot Rolling Mills

Meta TechX Engineers: Learn how to design gears for hot rolling mills using the required parameters, formulas, and essential insights from industry professionals. Discover the key factors that contribute to successful gear design in this in-depth article.Introduction:Designing gears for hot rolling mills requires meticulous attention to detail, expertise, and an understanding of the parameters and […]

Continue Reading....What is Module in Designing Gears

Meta TechX Engineers: In the vast field of mechanical engineering, gears play a crucial role in transmitting motion and power between two or more rotating shafts. The design of gears has evolved over the years, leading to the development of advanced techniques that optimize their efficiency and performance. One such technique is the implementation of […]

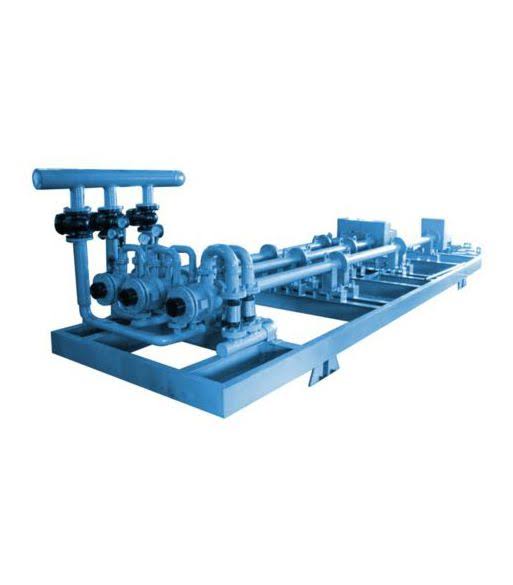

Continue Reading....Automatic Flow and Pressure Control Systems for Quenching Box

Meta TechX Engineers -: Discover the importance of automatic flow pressure control systems for quenching boxes. Learn how they enhance precision, increase productivity, and improve overall efficiency in the manufacturing process. In the world of industrial manufacturing, maintaining precise control over the quenching process is essential to ensure the desired outcomes of heat treatment. One […]

Continue Reading....Hot Rolling of Strip – Process, Parameters and Quality Defects

Strip Rolling in Hot Rolling Process: A in-short Overview by Meta TechX Engineers Introduction -: Strip rolling is a crucial step in the hot rolling process, which involves transforming metal Billets or Slabs into thin strips of various dimensions. Meta TechX Engineers aims to provide a comprehensive understanding of strip rolling, from the initial steps […]

Continue Reading....MPC Control Systems in Hot Rolling Mills Improving Efficiency and Quality

Introduction: Hot rolling mills operate under extreme conditions, including high temperatures and heavy loads. To optimize the performance and productivity of hot rolling mills, the implementation of model predictive control (MPC) systems has gained significant importance. In this article, we will explore the process of implementing MPC control in hot rolling mills and understand how […]

Continue Reading....What is Automatic Gauge Control System in Hot Rolling Mill

Introduction Hot rolling mills play a crucial role in the steel production process, shaping solid metal into various forms. To ensure the precise thickness of the rolled metal, manufacturers rely on advanced technology known as a Gauge Control System. In this article, we delve into the world of Gauge Control Systems, exploring how they work, […]

Continue Reading....The Major Control Systems in Hot Rolling Mill

Introduction -: Hot rolling mills are crucial in the manufacturing industry for processing metals such as steel and aluminum. These mills shape and deform metals at high temperatures to produce various products, including sheets, plates, and rods. To ensure smooth operations and quality output, hot rolling mills employ various control systems. In this article, we […]

Continue Reading....Implementing PID Control in Hot Rolling Mills for Enhanced Performance

To ensure precise control over the complex Hot rolling process, advanced control systems like Proportional-Integral-Derivative (PID) control are employed. In this article, we will dive into the process of implementing PID control in a hot rolling mill, exploring its key features and benefits. What is PID Control? PID control is a widely used feedback control […]

Continue Reading....Advance control system PID and MPC in Hot Rolling Mill

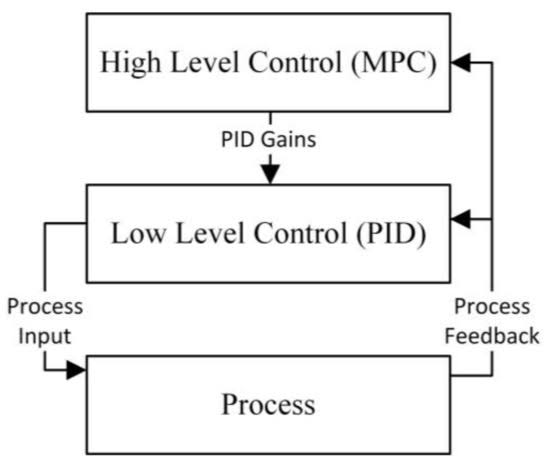

Introduction : Hot rolling mills employ advanced control systems to ensure efficient and precise operations. Among the various control techniques, proportional-integral-derivative (PID) control and model predictive control (MPC) play significant roles in optimizing the hot rolling process. Let’s take a closer look at these control strategies and how they are utilized in hot rolling mills. […]

Continue Reading....Tension Control System Ensuring Efficiency and Quality

Introduction : Tension control system in Hot Rolling process, which ensures the proper tension levels are maintained throughout the rolling operation. In this article, we will delve into the intricacies of the tension control system in hot rolling mills and explore its working principles, required parameters, and algorithms. What is a Tension Control System in […]

Continue Reading....How to Select Right Refractory Bricks for Reheating Furnace

Meta TechX Engineers – In the process of selecting refractory bricks for your reheating furnace. Choosing the right refractory bricks is crucial for the efficient operation of your reheating furnace. In this article, we will guide you through the process of selecting the most suitable refractory bricks for your specific needs. Let’s dive in!Why are […]

Continue Reading....Parameters to Design Reheating Furnace for Hot Rolling Mill

Lets understand basic concept about How to Design a Reheating Furnace for Hot Rolling Mill. Meta TechX Engineers will guide you through the process and parameters involved in designing an efficient reheating furnace. With our expertise in the field, we will provide you with valuable insights and recommendations to ensure a successful design. Meta Blogs […]

Continue Reading....Problems in Hot Rolling Process and Their Solutions

Meta TechX Engineers – Discover the major problems faced during the hot rolling process and explore effective solutions to overcome them. Improve the quality and efficiency of your metal manufacturing with these expert recommendations. Join us – Meta TechX Engineers Introduction In the field of metal manufacturing, the hot rolling process plays a crucial role […]

Continue Reading....Torque in Hot Rolling Process

Hot Rolling Torque: How to Calculate It? Introduction: As a professional in the field of hot rolling, I am often asked about the calculation of hot rolling torque. In this article, I will provide you with a comprehensive guide to understanding and calculating hot rolling torque. I will explain what hot rolling torque is, why […]

Continue Reading....Tensile Strength in Hot Rolled Products

Discover the significance of tensile strength in hot rolled products. Learn how it influences the performance and reliability of various industrial applications. Meta TechX Engineers Understanding Tensile Strength in Hot Rolled ProductsIntroduction:Hot rolled products are widely used in various industries due to their superior mechanical properties. One of the important characteristics to consider while evaluating […]

Continue Reading....Efficiency of Hot Rolling Mill

Improving the Efficiency of Hot Rolling Mill. Introduction – Hot rolling mills play a crucial role in the manufacturing process of various metal products. These mills transform metal ingots into desired shapes and sizes through a series of heating, rolling, and cooling processes. However, ensuring maximum efficiency in hot rolling mills is a constant challenge […]

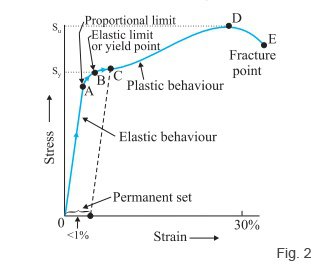

Continue Reading....How to enhance Yield Stress

How to Improve Yield Stress in Hot Rolled Products? Introduction: When it comes to hot rolled products, one of the most important properties to consider is yield stress. Yield stress refers to the amount of stress a material can withstand before it begins to deform permanently. In the context of hot rolled products, higher yield […]

Continue Reading....Roll Pass Design

Art of Designing Rolling Passes in Hot Rolling Process with Meta TechX Engineers Understanding the Hot Rolling Process In the world of metalworking, the hot rolling process is a crucial method for shaping metals into various forms. This process involves subjecting metal ingots or billets to high temperatures and passing them through a series of […]

Continue Reading....Thermo-Mechanically Treatment (TMT) and its process and parameters

Meta TechX Engineers -: Discover how TMT Bar quenching enhances material properties. Learn about the process, calculating flow rates, and vital parameters required for effective heat treatment. Meta Blog In the world of construction and engineering, the durability and strength of materials used play a crucial role. TMT bars, also known as Thermo-Mechanically Treated bars, […]

Continue Reading....Elongation

Elongation in the hot rolling process is a crucial phenomenon that plays a significant role in shaping and transforming metal materials. When subjected to intense heat and pressure, the metal undergoes plastic deformation, resulting in a remarkable increase in its length. This elongation occurs as the material is meticulously passed through a series of precisely […]

Continue Reading....Rolling Draft

Hot rolling draft refers to the reduction in thickness or size of a metal or alloy during the hot rolling process. It is the amount by which the initial thickness is decreased as the material passes through the rolling mill. The hot rolling draft plays a crucial role in shaping the final product’s dimensions and […]

Continue Reading....Stress and Strain

Stress and Strain… Stress and strain in hot rolling refer to the forces and deformations experienced by a material during the process of hot rolling, which is a metal working technique used to shape and form metal at high temperatures. Stress is the internal resistance or force per unit area within a material, while Strain […]

Continue Reading....Angle of Bite

Angle of Bite… The angle of bite in the hot rolling process refers to the angle at which the incoming material is fed into the rolling mill. It plays a crucial role in determining the quality and efficiency of the rolling process. A proper angle of bite ensures that the material is securely held between […]

Continue Reading....DPIC Rolls

The DPIC roll, Double Poured Indefinite Chilled Rolls also referred to as the Descaling, Pre-Interstand Cooling roll, holds immense significance within hot rolling mills. Its primary function is to eliminate scale and cool the material prior to its passage into the subsequent stand. By undertaking this process, the DPIC roll effectively enhances the surface quality […]

Continue Reading....Chilled Rolls

Chilled Rolls are cast iron based rolls alloyed with Nickel, Chromium and Molybdenum having a matrix of pearlite and carbide with flake graphite. The material has very good thermal properties coupled with property of imparting good surface finish to the product. A chilled work roll in hot rolling is a roll that has been cooled […]

Continue Reading....Work Rolls

Hot Rolling mill work rolls. In hot rolling mills, a work roll is a critical component that plays a vital role in the metal forming process. It is a cylindrical shape roll that is used to deform the metal and reduce its thickness. The work roll is positioned between the backup roll and the metal […]

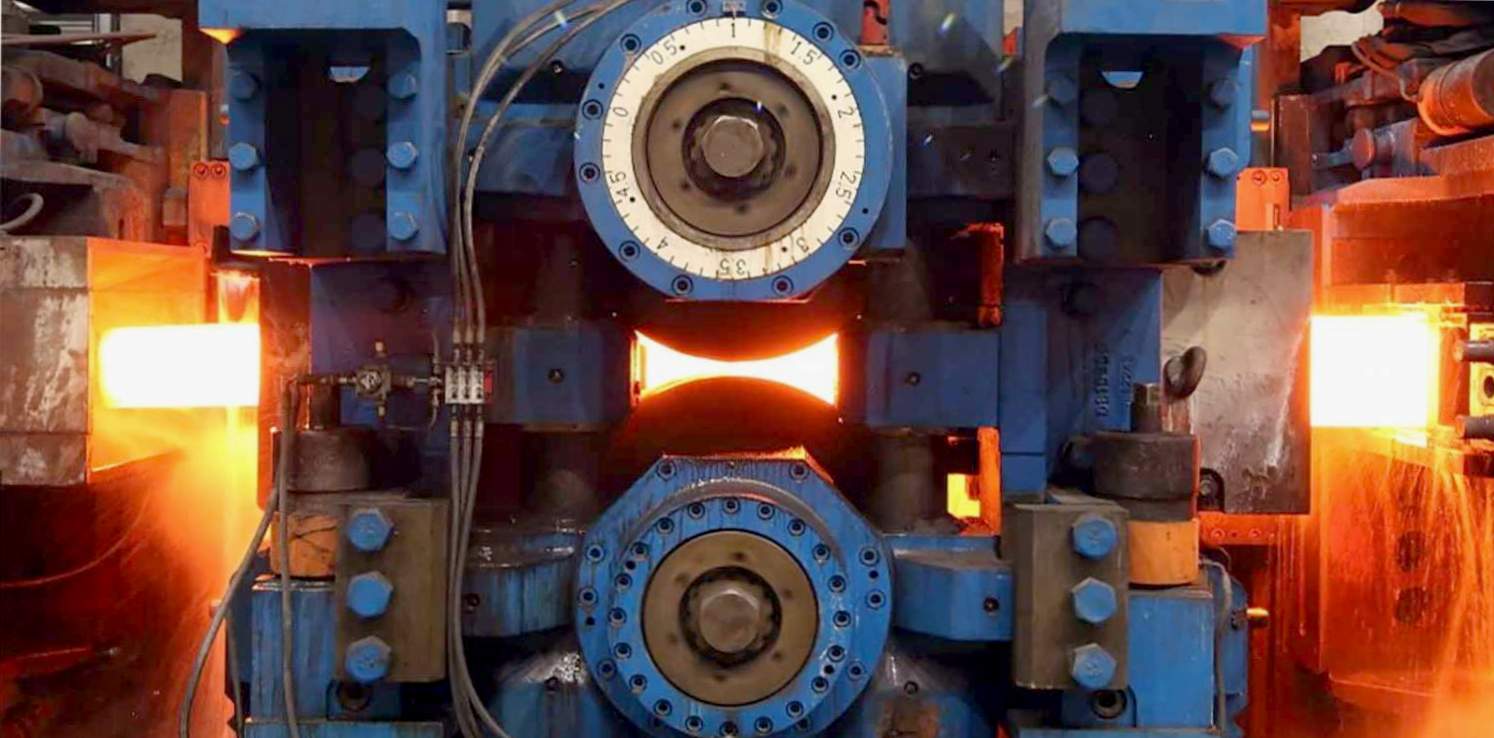

Continue Reading....Hot Rolling Process

Hot Rolling Mill Hot rolling is a fundamental process in the steel industry. It involves the heating and shaping of metal ingots or billets to produce various forms of steel products. The process begins with the heating of the metal to a high temperature, which makes it easier to shape and mold. Once heated, the […]

Continue Reading....