Charge mix calculation is the process of determining the optimal combination of raw materials—like scrap, pig iron, sponge iron, and ferroalloys—to be charged into the furnace. The goal is to achieve the desired chemical composition of the molten steel while minimizing cost and energy consumption.Charge mix calculation is the unsung hero of steelmaking—where metallurgy meets […]

Continue Reading....Tag: Meta TechX Engineers

Why EN-8 is preferred for Gear Shaft rather than Class 4 Material?

Gear shafts are made with EN8 rather than Class 4 material due to the specific mechanical and performance requirements of gear shafts, which Class 4 material cannot adequately meet. Here’s why: 1. Strength and Load-Bearing Capacity: 2. Wear Resistance: 3. Fatigue Resistance: 4. Machinability: 5. Heat Treatment and Customization: 6. Safety and Reliability: Key Summary: […]

Continue Reading....SOP for Induction Furnace

Standard Operating Procedure (SOP) for Induction Furnace in Steelmaking This detailed SOP covers all aspects of induction furnace operations, ensuring efficiency, safety, and consistent steel quality. 1. Objective To establish a standard procedure for operating an induction furnace in steelmaking, ensuring safe handling, efficient melting, and quality control. 2. Scope Applicable to all personnel involved […]

Continue Reading....Mechanics and Behavior of Metals

Mechanics and behavior of Metals, also known as the mechanics of materials, is a branch of mechanics that studies the behavior of solid materials under various forms of loading. This field is crucial in engineering because it helps to predict how materials will deform, break, or otherwise react under different conditions. Here are some key […]

Continue Reading....Tube Mill Operation Process and Control

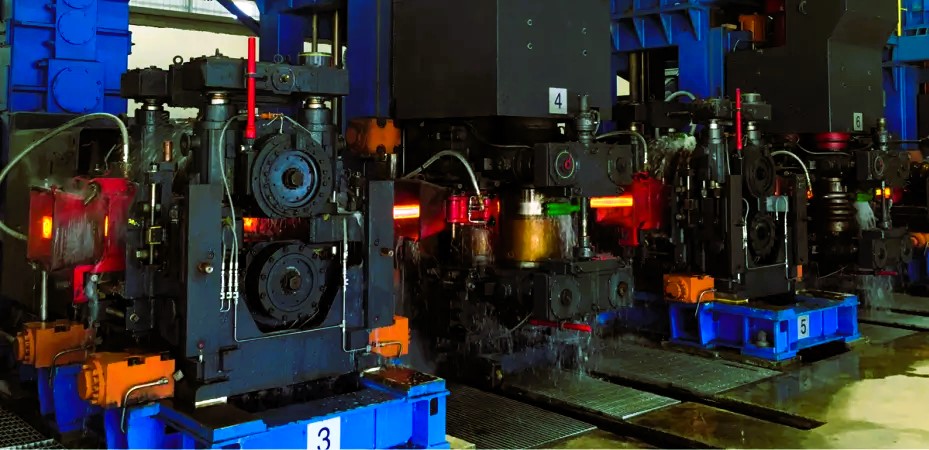

ERW Tube: Overview ERW (Electric Resistance Welded) tube is a type of steel pipe manufactured through a process in which a flat steel strip is shaped into a tubular form and welded along its longitudinal seam using electric resistance welding. ERW tubes are widely used in various industries, such as construction, automotive, agriculture, and energy, […]

Continue Reading....LD Converter Process in Steelmaking

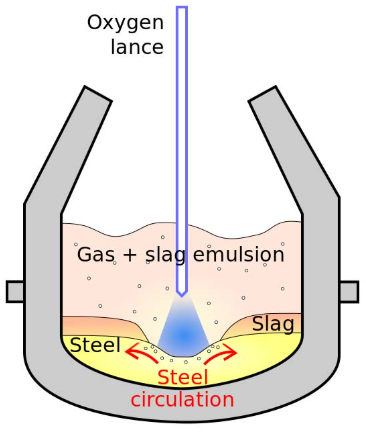

LD Process in Steelmaking: A Detailed Overview The LD (Linz-Donawitz) process, also known as the Basic Oxygen Furnace (BOF) process, is a primary steelmaking method that converts pig iron and scrap into high-quality steel. It is named after the Austrian towns of Linz and Donawitz, where it was first developed. The process relies on oxygen […]

Continue Reading....Hazard Identification and Risk Assessment in Induction Furnace

Hazard Identification and Risk Assessment (HIRA) in Induction Furnace Operations for Steel Making Induction furnaces are widely used in the steelmaking process due to their energy efficiency and ability to produce high-quality steel. However, their operation involves several hazards that require systematic identification and assessment to ensure workplace safety. Detailed explanation from MetaTechX Engineers: 1. […]

Continue Reading....Silico and Ferro Manganese in Steel Making

Silico and Ferro manganese in Steel Making Silico and ferro manganese are two types of ferroalloys used in the steelmaking process. They serve as sources of manganese, which is an essential element in steel production due to its properties that enhance the strength, hardness, and wear resistance of steel. Silico Manganese Silico manganese, an alloy […]

Continue Reading....Charge Mix and Composition in Liquid Metal

Fill all the details (Digits only) as given in the input form. Steel Melt Shop Calculator Charge Mix Calculator by Meta TechX Engineers Material Chemical Composition (%) Weight (kg) Scrap Pig Iron Sponge Iron Silico Manganese Calculate Composition Disclaimer -: This Calculator is for Educational Purpose only and has 75%+ accuracy, Which can help you […]

Continue Reading....Enhancing the lifespan of work rolls in a hot rolling mill

Enhancing the lifespan of work rolls in a hot rolling mill is crucial for improving productivity, reducing maintenance costs, and ensuring consistent product quality. Several key criteria should be considered to achieve this goal: By addressing these major criteria and implementing best practices, hot rolling mills can enhance the lifespan of work rolls, leading to […]

Continue Reading....Performance analysis of a hot rolling mill

Analyzing the performance of a hot rolling mill to improve productivity and reduce production costs and scrap value involves various factors including efficiency, yield, downtime, and quality control. Let’s break down the process and considerations: By analyzing these factors and identifying areas for improvement, such as reducing downtime, minimizing scrap, and optimizing processes, the overall […]

Continue Reading....Hot Rolling Calculator

Hot Rolling Calculator Hot Rolling Calculator by Prashant Goswami CTO MetaTechX Roll Diameter (mm): Initial Thickness (mm): Initial Width (mm): Final Thickness (mm): Final Width (mm): Motor RPM: Gear Ratio: Calculate Results:

Continue Reading....Converting a Problem into Solutions for Carbon Emissions

Discover how carbon emissions can be stored and converted into valuable products, while exploring the by-products generated in the process. Take a step towards a greener future! As the world becomes more aware of the environmental impact of human activities, a growing emphasis is being placed on reducing carbon emissions. Carbon emissions, mainly in the […]

Continue Reading....Types of Fuels Used in Steel Industries

Steel Industries: The Fueling Powerhouses Introduction Steel is one of the most important and versatile materials known to humanity. It plays a vital role in various industries, from construction to manufacturing. The production of steel, however, is an energy-intensive process that requires a significant amount of fuel. Let’s explore with MetaTechX Engineers the different types […]

Continue Reading....Understanding the Role of Ferrite

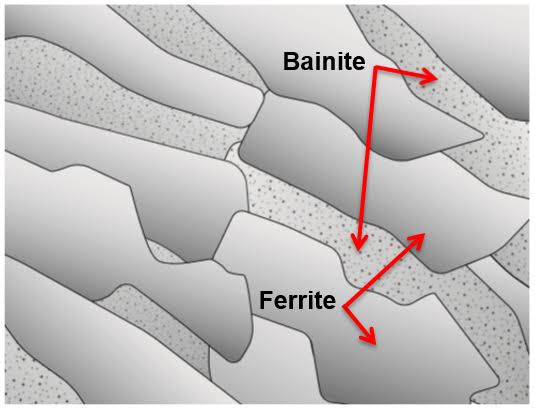

Steel Making: Understanding the Role of Ferrite Discover the secrets of steel making and the significance of ferrite. Learn how ferrite contributes to steel’s ductility, toughness, and magnetic properties. Explore FAQs about ferrite in steel Introduction with Meta TechX Engineers: Discover the secrets of steel making and the significance of ferrite. Learn how ferrite contributes […]

Continue Reading....Understanding the Power of Martensite in Steel

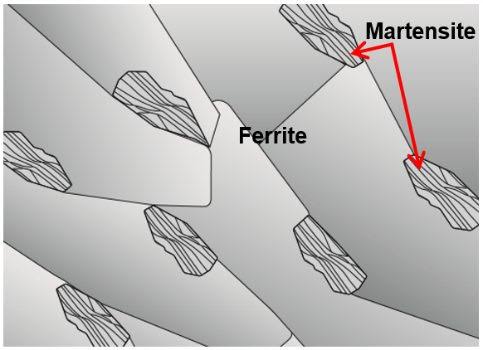

The Fascinating Process of Steel Making: Understanding Martensite Formation Introduction with Meta TechX Engineers: The Essence of Steel Making Every day, we encounter numerous products made of steel, from household appliances to towering skyscrapers. But have you ever wondered how steel is produced and what gives it its remarkable strength? In the world of metallurgy, […]

Continue Reading....Understanding the Impact of Sulphur on Steel Quality

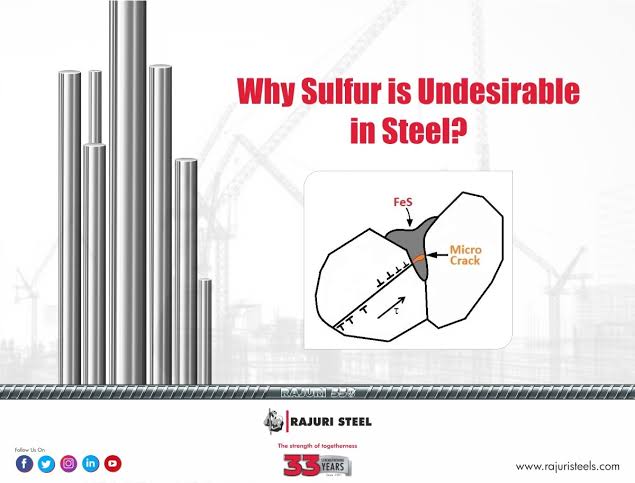

Introduction with Meta TechX Engineers The Role of Sulphur in Steel Making Steel, a vital material in the modern world, is known for its strength, durability, and versatility. However, the quality of steel can be significantly influenced by various factors, including the presence of impurities. One such impurity, sulphur, plays a crucial role in the […]

Continue Reading....Explore the basic understanding of Iron and Carbon diagram

An In-Depth Guide to Iron and Carbon Diagram Introduction with Meta TechX Engineers Steel making is a complex process that involves the manipulation of iron and carbon to create a material that is strong, durable, and versatile. This article will delve into the world of steel making, exploring the iron and carbon diagram, which is […]

Continue Reading....Understanding the Differences Between Inductotherm and Megatherm Induction Furnaces

Meta TechX Engineers : When it comes to melting metals, induction furnaces have become the go-to choice for many industries. These furnaces offer efficient and precise heating, making them ideal for a variety of applications. One crucial aspect of an induction furnace is its crucible design, as it directly impacts the melting process. In this […]

Continue Reading....Advantages and Limitations of Neutral Ramming Mass in Induction Furnace

Introduction In the realm of steel making, the use of quality refractory materials is paramount for ensuring efficient and cost-effective production. One such material is Neutral Ramming Mass, a specially formulated lining material used in induction furnaces. In this article, we will explore what Neutral Ramming Mass is, how it is made, and delve into […]

Continue Reading....Advantages and Limitations of Acidic Ramming Mass in Induction Furnace

Introduction In the vast realm of steelmaking, acidic Ramming Mass plays an indispensable role. This exceptional material is used in induction furnaces to line the inner walls and protect them from the harsh conditions of intense heat and chemical reactions. It not only ensures the longevity of the furnace but also contributes to the production […]

Continue Reading....Advantage and Limitations of Basic Ramming Mass in Induction Furnace

Introduction In the world of steel making, there are various key components that play a critical role in ensuring the production of high-quality steel. One such component is the basic ramming mass used in induction furnaces. This article will delve into the basics of basic ramming mass, its production process, as well as its advantages […]

Continue Reading....Quality of Ramming Mass in Induction Furnace and CCM

Enhancing Steelmaking Efficiency Introduction In the steelmaking process, the selection of the right materials is crucial for achieving optimal efficiency and productivity. One such material is ramming mass, which plays a vital role in the performance of induction furnaces and continuous casting machines. In this article, we will explore the types of ramming mass used […]

Continue Reading....Preventive Measures and Possible Causes for Induction Crucible Leakage

Introduction: Induction crucibles are essential components in various industrial processes, including metal melting and casting. However, one common issue faced by operators is the leakage of induction crucibles. This article aims to provide step-by-step preventive measures to avoid leakage and shed light on the potential reasons behind such occurrences. By implementing these strategies, operators can […]

Continue Reading....Steel Making Practice in Induction Furnace, A Step-by-Step Guide

Introduction Are you interested in learning about the intricate process of steel making in an induction furnace? Look no further, as this comprehensive guide will walk you through the step-by-step practice of producing high-quality steel using induction furnaces. From understanding the parameters to following the best practices, this article will provide you with the expertise […]

Continue Reading....Explore the step by step process of Lining an induction furnace

Introduction Are you familiar with the lining process and parameters of an induction furnace? In this article, we will walk you through the step by step process of lining an induction furnace, along with the necessary parameters to ensure its efficient operation. The lining of an induction furnace plays a crucial role in its performance […]

Continue Reading....A Complete Guide to TPM in the Hot Rolling Process

Meta TechX Engineers: In the world of manufacturing and industrial processes, TPM stands for Total Productive Maintenance. It is a method that focuses on the proactive and planned maintenance of machinery and equipment. TPM aims to maximize productivity, reduce downtime, and improve the overall efficiency of the production process. In this article, we will explore […]

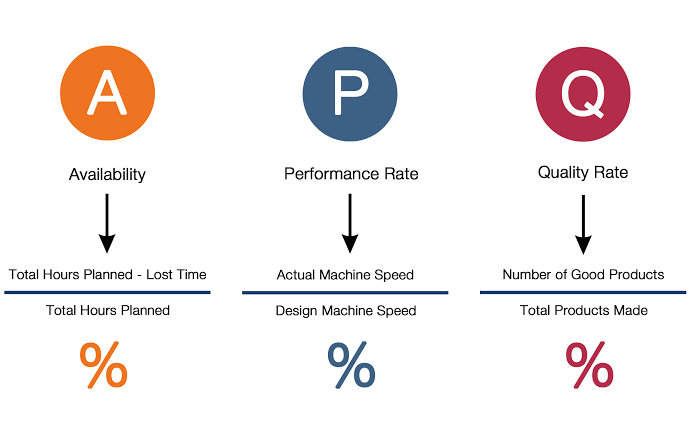

Continue Reading....Lession About Overall Equipment Efficiency and it’s Advantages

Meta TechX Engineers : In today’s rapidly evolving industrial landscape, optimizing efficiency and performance is of paramount importance for businesses. One key metric that helps manufacturers gauge their equipment’s effectiveness is Overall Equipment Efficiency (OEE). This article will delve into the concept of OEE, how to calculate it, and offer valuable insights on maintaining equipment […]

Continue Reading....Calculation for Actual Draft and Speed Adjustment

Hot rolling process Speed Adjustment…

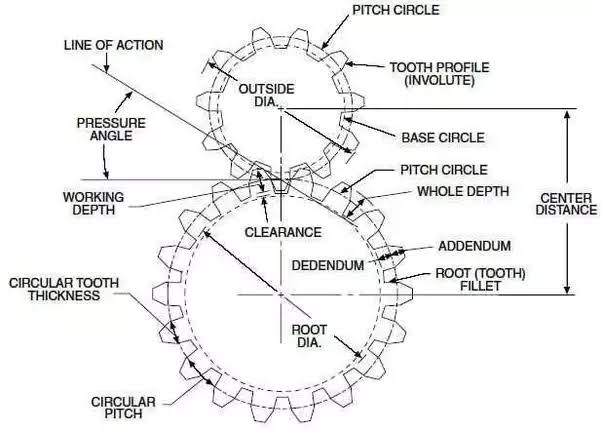

Continue Reading....What is Module in Designing Gears

Meta TechX Engineers: In the vast field of mechanical engineering, gears play a crucial role in transmitting motion and power between two or more rotating shafts. The design of gears has evolved over the years, leading to the development of advanced techniques that optimize their efficiency and performance. One such technique is the implementation of […]

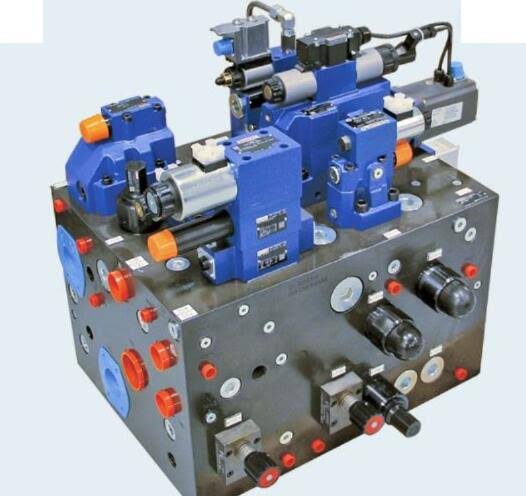

Continue Reading....Automatic Flow and Pressure Control Systems for Quenching Box

Meta TechX Engineers -: Discover the importance of automatic flow pressure control systems for quenching boxes. Learn how they enhance precision, increase productivity, and improve overall efficiency in the manufacturing process. In the world of industrial manufacturing, maintaining precise control over the quenching process is essential to ensure the desired outcomes of heat treatment. One […]

Continue Reading....Understanding the types of Breakout in Continuous Casting Machines

Meta TechX Engineers : Breakouts are a common occurrence in Continuous Casting Machines (CCM) used in the metal industry. These breakouts can lead to production downtime, material wastage, and safety hazards. It is crucial to understand the different types of breakouts, their possible causes, and effective ways to minimize them. In this article, we will […]

Continue Reading....Hot Rolling of Strip – Process, Parameters and Quality Defects

Strip Rolling in Hot Rolling Process: A in-short Overview by Meta TechX Engineers Introduction -: Strip rolling is a crucial step in the hot rolling process, which involves transforming metal Billets or Slabs into thin strips of various dimensions. Meta TechX Engineers aims to provide a comprehensive understanding of strip rolling, from the initial steps […]

Continue Reading....MPC Control Systems in Hot Rolling Mills Improving Efficiency and Quality

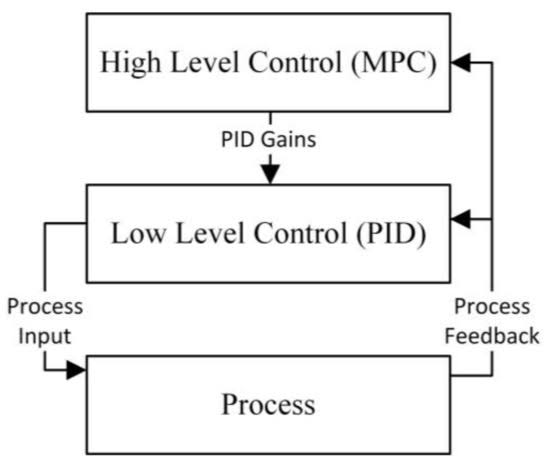

Introduction: Hot rolling mills operate under extreme conditions, including high temperatures and heavy loads. To optimize the performance and productivity of hot rolling mills, the implementation of model predictive control (MPC) systems has gained significant importance. In this article, we will explore the process of implementing MPC control in hot rolling mills and understand how […]

Continue Reading....What is Automatic Gauge Control System in Hot Rolling Mill

Introduction Hot rolling mills play a crucial role in the steel production process, shaping solid metal into various forms. To ensure the precise thickness of the rolled metal, manufacturers rely on advanced technology known as a Gauge Control System. In this article, we delve into the world of Gauge Control Systems, exploring how they work, […]

Continue Reading....The Major Control Systems in Hot Rolling Mill

Introduction -: Hot rolling mills are crucial in the manufacturing industry for processing metals such as steel and aluminum. These mills shape and deform metals at high temperatures to produce various products, including sheets, plates, and rods. To ensure smooth operations and quality output, hot rolling mills employ various control systems. In this article, we […]

Continue Reading....Implementing PID Control in Hot Rolling Mills for Enhanced Performance

To ensure precise control over the complex Hot rolling process, advanced control systems like Proportional-Integral-Derivative (PID) control are employed. In this article, we will dive into the process of implementing PID control in a hot rolling mill, exploring its key features and benefits. What is PID Control? PID control is a widely used feedback control […]

Continue Reading....Advance control system PID and MPC in Hot Rolling Mill

Introduction : Hot rolling mills employ advanced control systems to ensure efficient and precise operations. Among the various control techniques, proportional-integral-derivative (PID) control and model predictive control (MPC) play significant roles in optimizing the hot rolling process. Let’s take a closer look at these control strategies and how they are utilized in hot rolling mills. […]

Continue Reading....Tension Control System Ensuring Efficiency and Quality

Introduction : Tension control system in Hot Rolling process, which ensures the proper tension levels are maintained throughout the rolling operation. In this article, we will delve into the intricacies of the tension control system in hot rolling mills and explore its working principles, required parameters, and algorithms. What is a Tension Control System in […]

Continue Reading....Solenoid Control Relief Valve and it’s Advantages in Hydraulic Systems

Meta TechX Engineers : In hydraulic systems, the solenoid control relief valve plays a crucial role. But what exactly is a solenoid control relief valve and how does it operate? In this article, we will delve into the details of this essential component, exploring its functions and benefits. What is a Solenoid Control Relief Valve? […]

Continue Reading....Manifold it’s components, Operations and Advantages in Hydraulic Systems

Meta TechX Engineers: When it comes to hydraulic systems, manifold valves play a crucial role in ensuring efficient and precise control over fluid flow. But what exactly is a manifold valve in hydraulic systems, how does it operate, and what are its components and advantages? In this article, we will dive deep into the world […]

Continue Reading....How to Select Right Refractory Bricks for Reheating Furnace

Meta TechX Engineers – In the process of selecting refractory bricks for your reheating furnace. Choosing the right refractory bricks is crucial for the efficient operation of your reheating furnace. In this article, we will guide you through the process of selecting the most suitable refractory bricks for your specific needs. Let’s dive in!Why are […]

Continue Reading....Comparative Analysis of Aluminum Killed Steel and Silicon Killed Steel

Meta TechX Engineer’s Blog –Aluminum killed steel and Silicon killed steel are two commonly used types of steel. These variations of steel differ in composition and properties, which ultimately impact their advantages and disadvantages in different applications. This article will explore the specifics of aluminum killed steel and silicon killed steel, delving into their benefits […]

Continue Reading....Parameters to Design Reheating Furnace for Hot Rolling Mill

Lets understand basic concept about How to Design a Reheating Furnace for Hot Rolling Mill. Meta TechX Engineers will guide you through the process and parameters involved in designing an efficient reheating furnace. With our expertise in the field, we will provide you with valuable insights and recommendations to ensure a successful design. Meta Blogs […]

Continue Reading....Problems in Hot Rolling Process and Their Solutions

Meta TechX Engineers – Discover the major problems faced during the hot rolling process and explore effective solutions to overcome them. Improve the quality and efficiency of your metal manufacturing with these expert recommendations. Join us – Meta TechX Engineers Introduction In the field of metal manufacturing, the hot rolling process plays a crucial role […]

Continue Reading....Torque in Hot Rolling Process

Hot Rolling Torque: How to Calculate It? Introduction: As a professional in the field of hot rolling, I am often asked about the calculation of hot rolling torque. In this article, I will provide you with a comprehensive guide to understanding and calculating hot rolling torque. I will explain what hot rolling torque is, why […]

Continue Reading....Tensile Strength in Hot Rolled Products

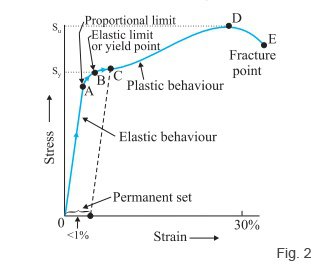

Discover the significance of tensile strength in hot rolled products. Learn how it influences the performance and reliability of various industrial applications. Meta TechX Engineers Understanding Tensile Strength in Hot Rolled ProductsIntroduction:Hot rolled products are widely used in various industries due to their superior mechanical properties. One of the important characteristics to consider while evaluating […]

Continue Reading....Efficiency of Hot Rolling Mill

Improving the Efficiency of Hot Rolling Mill. Introduction – Hot rolling mills play a crucial role in the manufacturing process of various metal products. These mills transform metal ingots into desired shapes and sizes through a series of heating, rolling, and cooling processes. However, ensuring maximum efficiency in hot rolling mills is a constant challenge […]

Continue Reading....How to enhance Yield Stress

How to Improve Yield Stress in Hot Rolled Products? Introduction: When it comes to hot rolled products, one of the most important properties to consider is yield stress. Yield stress refers to the amount of stress a material can withstand before it begins to deform permanently. In the context of hot rolled products, higher yield […]

Continue Reading....Roll Pass Design

Art of Designing Rolling Passes in Hot Rolling Process with Meta TechX Engineers Understanding the Hot Rolling Process In the world of metalworking, the hot rolling process is a crucial method for shaping metals into various forms. This process involves subjecting metal ingots or billets to high temperatures and passing them through a series of […]

Continue Reading....Continuous Casting Preparation

Preparing a continuous casting machine before starting the process is crucial to ensure the production of high-quality castings. Here is a step-by-step guide on how to prepare a continuous casting machine: Join Us For Updates Step 1: Inspection and Maintenance – Thoroughly inspect the continuous casting machine and its components for any signs of damage, […]

Continue Reading....CCM

Continuous casting is a process that involves the production of metal products in a continuous manner, without the need for individual casting molds for each product. This method offers several advantages over traditional casting methods. One of the main benefits of continuous casting is the ability to produce long, continuous lengths of metal products, such […]

Continue Reading....CPC- Calcined Petroleum Coke

Calcined Petroleum Coke (CPC) is an indispensable component in the steelmaking industry. Its primary function is to serve as a carbon additive, effectively increasing the carbon content of molten iron. This essential role not only helps to reduce impurities but also contributes to the overall enhancement of steel quality. By introducing Calcined Petroleum Coke into […]

Continue Reading....Thermo-Mechanically Treatment (TMT) and its process and parameters

Meta TechX Engineers -: Discover how TMT Bar quenching enhances material properties. Learn about the process, calculating flow rates, and vital parameters required for effective heat treatment. Meta Blog In the world of construction and engineering, the durability and strength of materials used play a crucial role. TMT bars, also known as Thermo-Mechanically Treated bars, […]

Continue Reading....Elongation

Elongation in the hot rolling process is a crucial phenomenon that plays a significant role in shaping and transforming metal materials. When subjected to intense heat and pressure, the metal undergoes plastic deformation, resulting in a remarkable increase in its length. This elongation occurs as the material is meticulously passed through a series of precisely […]

Continue Reading....Rolling Draft

Hot rolling draft refers to the reduction in thickness or size of a metal or alloy during the hot rolling process. It is the amount by which the initial thickness is decreased as the material passes through the rolling mill. The hot rolling draft plays a crucial role in shaping the final product’s dimensions and […]

Continue Reading....Stress and Strain

Stress and Strain… Stress and strain in hot rolling refer to the forces and deformations experienced by a material during the process of hot rolling, which is a metal working technique used to shape and form metal at high temperatures. Stress is the internal resistance or force per unit area within a material, while Strain […]

Continue Reading....Angle of Bite

Angle of Bite… The angle of bite in the hot rolling process refers to the angle at which the incoming material is fed into the rolling mill. It plays a crucial role in determining the quality and efficiency of the rolling process. A proper angle of bite ensures that the material is securely held between […]

Continue Reading....DPIC Rolls

The DPIC roll, Double Poured Indefinite Chilled Rolls also referred to as the Descaling, Pre-Interstand Cooling roll, holds immense significance within hot rolling mills. Its primary function is to eliminate scale and cool the material prior to its passage into the subsequent stand. By undertaking this process, the DPIC roll effectively enhances the surface quality […]

Continue Reading....Chilled Rolls

Chilled Rolls are cast iron based rolls alloyed with Nickel, Chromium and Molybdenum having a matrix of pearlite and carbide with flake graphite. The material has very good thermal properties coupled with property of imparting good surface finish to the product. A chilled work roll in hot rolling is a roll that has been cooled […]

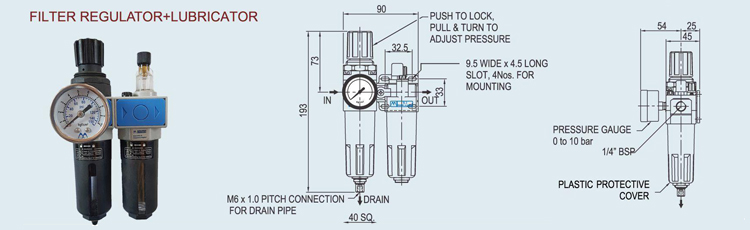

Continue Reading....FRL Unit

An FRL unit is a combination device consisting of a Filter (F), Regulator (R), and Lubricator (L) that is used to ensure clean air and protection of downstream equipment, regulation of air pressure, and lubrication of moving parts in a compressed air system. The filter removes contaminants and moisture from the compressed air, the regulator […]

Continue Reading....Induction Furnace in Steel Making

Meta TechX Engineers – An Electric induction furnace is a type of furnace used for melting metal and creating various metal products. It is widely utilized in the manufacturing industry due to its efficiency, precision, and versatility. Induction furnaces use electromagnetic induction to generate heat, resulting in a controlled and energy-efficient melting process. The principle […]

Continue Reading....Work Rolls

Hot Rolling mill work rolls. In hot rolling mills, a work roll is a critical component that plays a vital role in the metal forming process. It is a cylindrical shape roll that is used to deform the metal and reduce its thickness. The work roll is positioned between the backup roll and the metal […]

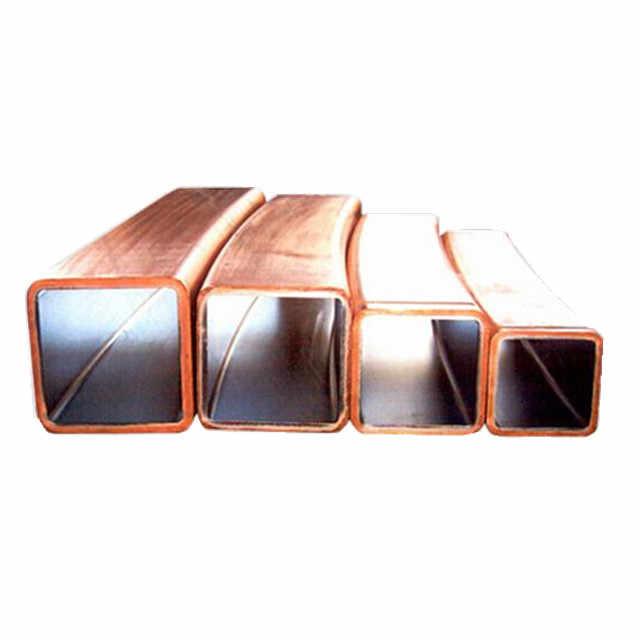

Continue Reading....Select the Right Quality of Mold Tube for CCM

Meta TechX Engineer’s Blog – When it comes to Continuous Casting Machines (CCM), selecting the right mold tube is crucial for ensuring high-quality output. The mold plays a significant role in the casting process, impacting the overall efficiency, productivity, and quality of the final product. In this article, we will discuss how to select the […]

Continue Reading....Advantage and Disadvantage of Silicon Content in Steel

Silicon in Steel Making… Silicon plays an impotent role in the steelmaking process, as it reacts with oxygen and other impurities in the molten steel. This reaction forms silicon dioxide, a compound that rises to the surface, allowing it to be easily removed. By removing the impurities, silicon helps improve the quality of the steel. […]

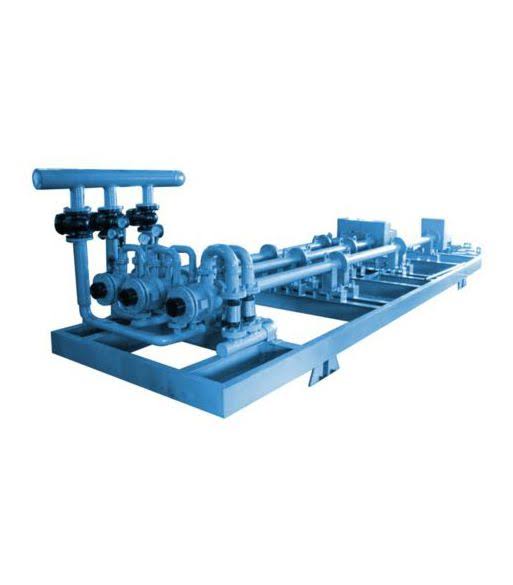

Continue Reading....Hydraulic Power Unit

Hydraulic Power Unit (HPU) is a piece of equipment that generates and transfers hydraulic energy to other hydraulic components within a system. It is commonly used to power hydraulic machinery and equipment. The main components of a hydraulic power unit include: The operation of a hydraulic power unit involves the following steps: Maintenance of a […]

Continue Reading....